Posts Tagged ‘Part Count’

How Startups Can Move Prototypes Out Of The Lab And Onto The Factory Floor

Startups are good at making something work in the lab for the first time. However, startups are not good at moving their one-in-a-row prototypes to the manufacturing floor. But if startups are to scale, that’s exactly what they must do. For startups to be successful, they must continually change the design to enable the next level of production volume.

Startups are good at making something work in the lab for the first time. However, startups are not good at moving their one-in-a-row prototypes to the manufacturing floor. But if startups are to scale, that’s exactly what they must do. For startups to be successful, they must continually change the design to enable the next level of production volume.

To do that, I propose a 10, 100, 1000 approach.

After the one-in-a-row prototypes, how will you make 10? Can the crude assembly process produce 10 prototypes? If so, use the same crude assembly process. The cost of the prototypes is not a problem at this stage, so there’s no need to change the manufacturing processes to reduce the cost of the components. And at these low volumes, it’s unlikely the existing assembly process is too labor intensive (you’re only making 10) so there’s likely no need to change the process from a “time to build” perspective. But if the variation generated by the assembly process leads to prototypes that don’t function properly, the variation of the assembly process must be controlled with poke-yoke measures. Add only the controls you need because that work takes money and time which you don’t have as a startup. Otherwise, build the next 10 like you built the first one.

After the first 10, how will you make the next 100? Building 100 units doesn’t sound like a big deal, but 100 is a lot more than 10. Do you have suppliers who will sell you 100 of each part? Do you have the factory space to store the raw materials? Do you have the capability and capacity to inspect the incoming material? Do you have the money to buy all the parts? If the answer to all these questions is yes, it’s time to ask the difficult questions.

The cost of the units is likely still not a problem because the volumes are still small. There’s likely no need to change the manufacturing process (e.g., moving from machining to casting) to reduce the cost of the units. And it’s unlikely the time to build the units is becoming a problem because a super long build time isn’t all that problematic when building 100 units. So it’s not time to reduce the number of parts in the product (product simplification through part count reduction – aka, Design for Assembly). But it’s likely time to reduce the variation of the assembly process and eliminate the rework-inspect-test loop that comes when each unit that emerges from the production process is different. It’s time for assembly instructions, assembly fixtures, dedicated tools at each workstation, measurement tools to inspect the final product, and a group of quality professionals to verify the product is built correctly.

After the first 100, how will you make the next 1000? If you can, avoid changing the design, the manufacturing processes, or the assembly process. Keep everything the same and build 1000 units just as you built the first 100. But that’s unlikely because the cost will be too high and the assembly time will be too long. For the most expensive parts, consider changing the manufacturing process to one that can support higher volumes at a lower cost. You likely will have to buy the parts from another supplier who specializes in the new process and for that, you’ll need a purchasing professional with a quality background. To reduce build time, do Design for Assembly (DFA) to eliminate parts (fasteners and connectors). And for the processes that generate the highest rework times and scrap, add the necessary process controls to reduce variation and eliminate defects. Do the minimum (lowest investment dollars and design time) to achieve the appropriate cost and quality levels and declare success.

After 1000 units, it’s time to automate and move to new manufacturing processes. For the longest assembly processes, change the design (the parts themselves) to enable automated assembly processes. For the highest cost parts, change the parts (the design itself) to enable the move to manufacturing processes with lower cost signatures. The important idea is that the design and its parts must change to automate and enable lower-cost manufacturing processes. You’ll need new suppliers and purchasing professionals to bring them on board. You’ll need quality professionals to verify the quality of the incoming parts and the output of the assembly process. You’ll need manufacturing and automation engineers to simplify and automate the manufacturing processes.

The 10, 100, 1000 process is rather straightforward but it’s difficult because it requires judgement. At what production volume do you move to higher volume manufacturing processes to reduce costs? At what production volumes do you change the design to automate the assembly process to reduce assembly time? At what point do you add assembly fixtures to reduce variation? Which assembly processes do you improve and which do you leave as-is? When do you spend money on improvements and when do you buckle down and grind it out without making improvements?

The answer to all these questions is the same – hire a pro who has done it before. Hire a pro who knows when (and how) to do Design for Manufacturing and when to keep the design as it is. Hire a pro who knows when (and how) to add poke-yoke solutions and when to keep the assembly process as it is and rework the defects because that’s the lowest cost and fastest way to go. Hire a pro who knows when to change the design to reduce assembly time (Design for Assembly) and when to change the design and invest in automated assembly. Hire a pro who knows how (and when) to implement a full-blown quality system.

When it’s time to move from the lab to the factory floor, it’s time to hire a pro.

Image credit — Jim Roberts Gallery

It’s not so easy to move manufacturing work back to the US.

I hear it’s a good idea to move manufacturing work back to the US.

Before getting into what it would take to move manufacturing work back to the US, I think it’s important to understand why manufacturing companies moved their work out of the US. Simply put, companies moved their work out of the US because their accounting systems told them they would make more money if they made their products in countries with lower labor costs. And now that labor costs have increased in these no longer “low-cost countries”, those same accounting systems think there’s more money to be made by bringing manufacturing back to the US.

At a low level of abstraction, manufacturing, as a word, is about making discrete parts like gears, fenders, and tires using machines like gear shapers, stamping machines, and injection molding machines. The cost of manufacturing the parts is defined by the cost of the raw material, the cost of the machines, the cost of energy to power the machines, the cost of the factory, and the cost of the people to run the machines. And then there’s assembly, which, as a word, is about putting those discrete parts together to make a higher-level product. Where manufacturing makes the gears, fenders, and tires, assembly puts them together to make a car. And the cost of assembly is defined by the cost of the factory, the cost of fixtures, and the cost of the people to assemble the parts into the product. And the cost of the finished product is the sum of the cost of making the parts (manufacturing) and the cost of putting them together (assembly).

It seems pretty straightforward to make more money by moving the manufacturing of discrete parts back to the US. All that has to happen is to find some empty factory space, buy new machines, land them in the factory, hire the people to run the machines, train them, source the raw material, hire the manufacturing experts to reinvent/automate the manufacturing process to reduce cycle time and reduce labor time and then give them six months to a year to do that deep manufacturing work. That’s quite a list because there’s little factory space available that’s ready to receive machines, the machines cost money, there are few people available to do manufacturing work, the cost to train them is high (and it takes time and there are no trained trainers). But the real hurdles are the deep work required to reinvent/automate the process and the lack of manufacturing experts to do that work. The question you should ask is – Why does the manufacturing process have to be reinvented/automated?

There’s a dirty little secret baked into the accounting systems’ calculations. The cost accounting says there can be no increased profit without reducing the time to make the parts and reducing the labor needed to make them. If the work is moved from country A to country B and the costs (cycle time, labor hours, labor rate) remain constant, the profit remains constant. Simply moving from country A to country B does nothing. Without the deep manufacturing work, profits don’t increase. And if your country doesn’t have the people with the right expertise, that deep manufacturing work cannot happen.

And the picture is similar for moving assembly work back to the US. All that has to happen is to find empty factory space, hire and train people to do the assembly work, reroute the supply chains to the new factory, redesign the product so it can be assembled with an automated assembly line, hire/train the people to redesign the product so it can be assembled in an automated way, design the new automated assembly process, build it, test it, hire/train the automated assembly experts to do that work, hire the people to support and run the automated assembly line, and pay for the multi-million-dollar automated assembly line. And the problems are similar. There’s not a lot of world-class factory space, there are few people available to run the automated assembly line, and the cost of the automated assembly line is significant. But the real problems are the lack of experts to redesign the product for automated assembly and the lack of expertise to design, build, and validate the assembly line. And here are the questions you should ask – Why do we need to automate the assembly process and why does the product have to be redesigned to do that?

It’s that dirty little secret rearing its ugly head again. The cost accounting says there can be no increased profit without reducing the labor to assemble the parts. make them. If the work is moved from country A to country B and the assembly costs (labor hours, labor rate) remain constant, the profit remains constant. Simply moving from country A to country B does nothing. Without deep design work (design for automated assembly) and ultra-deep automated assembly work, profits don’t increase. And if your country doesn’t have the people with the right expertise, that deep design and automated assembly work cannot happen.

If your company doesn’t have the time, money, and capability to reinvent/automate manufacturing processes, it’s a bad idea to move manufacturing work back to the US. It simply won’t work. Instead, find experts who can help you develop/secure the capability to reinvent/automate manufacturing processes to reduce the cost of manufacturing.

If your company doesn’t have the time, money, and capability to design products for automated assembly and to design, build, and validated automated assembly systems, it’s a bad idea to move assembly work back to the US. It, too, simply won’t work. Instead, partner with experts who know how to do that work so you can reduce the cost of assembly.

The best time to design cost out of our products is now.

With inflation on the rise and sales on the decline, the time to reduce costs is now.

With inflation on the rise and sales on the decline, the time to reduce costs is now.

But before you can design out the cost you’ve got to know where it is. And the best way to do that is to create a Pareto chart that defines product cost for each subassembly, with the highest cost subassemblies on the left and the lowest cost on the right. Here’s a pro tip – Ignore the subassemblies on the right.

Use your costed Bill of Materials (BOMs) to create the Paretos. You’ll be told that the BOMs are wrong (and they are), but they are right enough to learn where the cost is.

For each of the highest-cost subassemblies, create a lower-level Pareto chat that sorts the cost of each piece-part from highest to lowest. The pro tip applies here, too – Ignore the parts on the right.

Because the design community designed in the cost, they are the ones who must design it out. And to help them prioritize the work, they should be the ones who create the Pareto charts from the BOMs. They won’t like this idea, but tell them they are the only ones who can secure the company’s future profits and buy them lots of pizza.

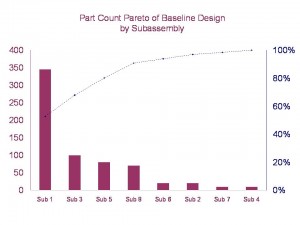

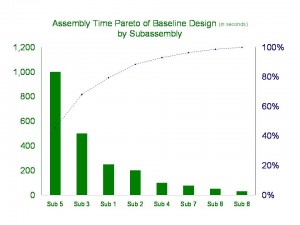

And when someone demands you reduce labor costs, don’t fall for it. Labor cost is about 5% of the product cost, so reducing it by half doesn’t get you much. Instead, make a Pareto chart of part count by subassembly. Focus the design effort on reducing the part count of subassemblies on the left. Pro tip – Ignore the subassemblies on the right. The labor time to assemble parts that you design out is zero, so when demand returns, you’ll be able to pump out more products without growing the footprint of the factory. But, more importantly, the cost of the parts you design out is also zero. Designing out the parts is the best way to reduce product costs.

Pro tip – Set a cost reduction goal of 35%. And when they complain, increase it to 40%.

In parallel to the design work to reduce part count and costs, design the test fixtures and test protocols you’ll use to make sure the new, lower-cost design outperforms the existing design. Certainly, with fewer parts, the new one will be more reliable. Pro tip – As soon as you can, test the existing design using the new protocols because the only way to know if the new one is better is to measure it against the test results of the old one.

And here’s the last pro tip – Start now.

Image credit — aisletwentytwo

An Environmental Call-To-Arms for Industry

What is your obligation to improve the health of our planet?

What is your obligation to improve the health of our planet?

For the CEO – Look around. Look at Europe. Look at China’s plans. Look at the startups. I know you want to achieve your growth objectives, but if you don’t take seriously the race toward cleaner products and services, you’ll go out of business. You can see this as a problem or an opportunity. Bury your head or put on your track shoes and run! It’s your choice.

Look at the oceans. Look at the landfills. Look at the rise in global temperatures. Just look. This isn’t about ROI, this is about survival. Growth objectives aside, no one will buy things when they are struggling to survive in an uncertain future. Your same old dirty products won’t cut it anymore. So, what are you going to do?

For an example of a path forward, look to the companies in the oil business. Their recipe is clear. They’ve got to use their large but ever-diminishing profits to buy themselves into technologies and industries that will ultimately eat their core business. Though the timing is uncertain, it’s certain that improvements in cleaner technologies will demand they make the change.

Whatever you do, don’t wait. You don’t have much time. Cleaner technologies are getting better every day. It’s time to start.

For Marketing – Look at the upstarts. Look at the powerful companies in adjacent markets who will soon be your direct competitors. Look at your stodgy, unprofitable competitors who are now sufficiently desperate to try anything. Their next marketing push will be built on the bedrock of an improved planet. They’ll be almost as good as you in the traditional areas of productivity and quality and they’ll blow your doors off with their meaner and greener products. Customers will choose green over brown. And they’ll look for real improvements that make the planet smile. The time for green-washing is past. That trick is out of gas.

You need to help customers with new jobs to be done. They care about their environment. They care about their carbon footprint. They care about clean water. And they care about recycling and reuse. It’s real. They care. Now it’s up to you to help them make progress in these areas. It will be a tough road to convince your company that things need to change, but that’s why you’re in Marketing.

You’re already behind. It’s time to start. And it’s up to you to lead the charge.

For Manufacturing – Look at your Value Stream Maps (VSMs). Assign a carbon footprint to each link in the chain. And do the same with water consumption. Assess each process step for carbon and water and rank them worst to best. For the worst, run carbon kaizens and improve the carbon footprint. And run water kaizens for the thirstiest processes.

And look again at your VSMs, and look more broadly. Look back into the supply chain, rank for carbon and water and improve the ones that need the treatment. And teach your suppliers how to do it. And look forward into your distribution channels and improve or eliminate the worst actors. And then propose to Marketing that you teach your customers how to use VSMs to clean up their act. And challenge Engineering to change the design to eliminate the remaining bad actors.

You’ve made good progress with your value streams. Now it’s time to help others make the progress that must be made. As subject matter experts, it’s your time to shine. And, please, start now.

For Engineering – Look at your products. Look at how they’re used. Look at how they’re delivered. Look at how they’re made. Look at how they’re recycled. Sure, your products provide good functionality, but throughout their life cycle they also create carbon dioxide and consume water. And you’re the only ones that can design out the environmental impact.

Learn how to do a Life Cycle Assessment (LCA). Learn which elements of the product create the largest problems. For all the parts that make up the product, sort them worst to best to prioritize the design work. It’s time for radical part count reduction. Try to design out half the parts. It’s possible. And the payoff is staggering. What’s the carbon footprint of a part that was designed out of the product?

Or, to make a more radical improvement, consider an Innovation Burst Event (IBE) to make a fundamental change in the way your products/services impact the environment. With this approach, your innovation work, by definition, will make the planet smile.

It’s time to be open-minded. Ask Manufacturing for the worst processes (including supply chain and distribution) and try to design them out. Design out the part, or change the material, or change the design to enable a friendlier process. Manufacturing can only improve a bad process, but you can design them out altogether. There’s power in that, but with power comes responsibility.

And it’s time for you to take responsibility.

For Everyone in Industry – Regardless of your company, your country or your political affiliation, we can all agree that all our lives get better as the health of our planet improves. And everyone can agree that cleaner air is better. And everyone can agree it’s the same for our water – cleaner is better. And that’s a whole lot of agreement.

As industry leaders, I challenge you to build on that common ground. As industry leaders, I challenge you to improve our planet one product at a time and one process at a time. And as industry leaders, I challenge you to help each other. There’s no competitive disadvantage when you help a company outside your industry. And there’s no shame in learning from companies outside your industry. And it’s good for the planet and profits. There’s nothing in the away. It’s time to start.

As an industry leader, if you want to make a difference in the health of our planet, send me an email at mike@shipulski.com and we will help each other.

Image credit – halfrain

Fix The Economy – Connect The Engineer To The Factory

Rumor has it, manufacturing is back. Yes, manufacturing jobs are coming back, but they’re coming back in dribbles. (They left in a geyser, so we still have much to do.) What we need is a fire hose of new manufacturing jobs.

Rumor has it, manufacturing is back. Yes, manufacturing jobs are coming back, but they’re coming back in dribbles. (They left in a geyser, so we still have much to do.) What we need is a fire hose of new manufacturing jobs.

Manufacturing jobs are trickling back from low cost countries because companies now realize the promised labor savings are not there and neither is product quality. But a trickle isn’t good enough; we need to turn the tide; we need the Mississippi river.

For flow like that we need a fundamental change. We need labor costs so low our focus becomes good quality; labor costs so low our focus becomes speed to market; labor costs so low our focus becomes speed to customer. But the secret is not labor rate. In fact, the secret isn’t even in the factory.

The secret is a secret because we’ve mistakenly mapped manufacturing solely to making (to factories). We’ve forgotten manufacturing is about designing and making. And that’s the secret: designing – adding product thinking to the mix. Design out the labor.

There are many names for designing and making done together. Most commonly it’s called concurrent engineering. Though seemingly innocuous, taken together, those words have over a thousand meanings layered with even more nuances. (Ask someone for a simple description of concurrent engineering. You’ll see.) It’s time to take a step back and demystify designing and making done together. We can do this with two simple questions:

- What behavior do we want?

- How do we get it?

What’s the behavior we want? We want design engineers to understand what drives cost in the factory (and suppliers’ factories) and design out cost. In short, we want to connect the engineer to the factory.

Great idea. But what if the factory and engineer are separated by geography? How do we get the behavior we want? We need to create a stand-in for the factory, a factory surrogate, and connect the engineer to the surrogate. And that surrogate is cost. (Cost is realized in the factory.) We get the desired behavior when we connect the engineer to cost.

When we make engineering responsible for cost (connect them to cost), they must figure out where the cost is so they can design it out. And when they figure out where the cost is, they’re effectively connected to the factory.

But the engineers don’t need to understand the whole factory (or supply chain), they only need to understand places that create cost (where the cost is.) To understand where cost is, they must look to the baseline product – the one you’re making today. To help them understand supply chain costs, ask for a Pareto chart of cost by part number for purchased parts. (The engineers will use cost to connect to suppliers’ factories.) The new design will focus on the big bars on the left of the Pareto – where the supply chain cost is.

To help them understand your factory’s cost, they must make two more Paretos. The first one is a Pareto of part count by major subassembly. Factory costs are high where the parts are – time to put them together. The second is a Pareto chart of process times. Factory costs are high where the time is – machine capacity, machine operators, and floor space.

To make it stick, use design reviews. At the first design review – where their design approach is defined – ask engineering for the three Paretos for the baseline product. Use the Pareto data to set a cost reduction goal of 50% (It will be easily achieved, but not easily believed.) and part count reduction goal of 50%. (Easily achieved.) Here’s a hint for the design review – their design approach should be strongly shaped by the Paretos.

Going forward, at every design review, ask engineering to present the three Paretos (for the new design) and cost and part count data (for the new design.) Engineering must present the data themselves; otherwise they’ll disconnect themselves from the factory.

To seal the deal, just before full production, engineering should present the go-to-production Paretos, cost, and part count data.

What I’ve described may not be concurrent engineering, but it’s the most profitable activity you’ll ever do. And, as a nice side benefit, you’ll help turn around the economy one company at a time.

Radically Simplify Your Value Stream – Change Your Design

The next level of factory simplification won’t come from your factory. It will come from outside your factory. The next level of simplification will come from upstream savings – your suppliers’ factories – and downstream savings – your distribution system. And this next level of simplification will create radically shorter value streams (from raw materials to customer.)

The next level of factory simplification won’t come from your factory. It will come from outside your factory. The next level of simplification will come from upstream savings – your suppliers’ factories – and downstream savings – your distribution system. And this next level of simplification will create radically shorter value streams (from raw materials to customer.)

To reinvent your value stream, traditional lean techniques – reduction of non-value added (NVA) time through process change – aren’t the best way. The best way is to eliminate value added (VA) time through product redesign – product change. Reduction of VA time generates a massive NVA savings multiple. (Value streams are mostly NVA with a little VA sprinkled in.) At first this seems like backward thinking (It is bit since lean focuses exclusively on NVA.), but NVA time exists only to enable VA time (VA work). No VA time, no associated NVA time.

Value streams are all about parts (making them, counting them, measuring them, boxing them, moving them, and un-boxing them) and products (making, boxing, moving.) The making – touch time, spindle time – is VA time and everything else is VA time. Design out the parts themselves (VA time) and NVA time is designed out. Massive multiple achieved.

But the design community is the only group that can design out the parts. How to get them involved? Not all parts are created equal. How to choose the ones that matter? Value streams cut across departments and companies. How to get everyone pulling together?

Watch the video: link to video. (And embedded below.)

A Recipe for Unreasonable Profits

There’s an unnatural attraction to lean – a methodology to change the value stream to reduce waste. And it’s the same with Design for Manufacturing (DFM) – a methodology to design out cost of your piece-parts. The real rain maker is Design for Assembly (DFA) which eliminates parts altogether (50% reductions are commonplace.) DFA is far more powerful.

There’s an unnatural attraction to lean – a methodology to change the value stream to reduce waste. And it’s the same with Design for Manufacturing (DFM) – a methodology to design out cost of your piece-parts. The real rain maker is Design for Assembly (DFA) which eliminates parts altogether (50% reductions are commonplace.) DFA is far more powerful.

The cost for a designed out part is zero. Floor space for a designed out part is zero. Transportation cost for a designed out part is zero. (Can you say Green?) From a lean perspective, for a designed out part there is zero waste. For a designed out part the seven wastes do not apply.

Here’s a recipe for unreasonable profits:

Design out half the parts with DFA. For the ones that remain, choose the three highest cost parts and design out the cost. Then, and only then, do lean on the manufacturing processes.

For a video version of the post, see this link: (Video embedded below.)

A Recipe for Unreasonable Profits.

I can name that tune in three notes.

More with more doesn’t cut it anymore, just not good enough.

More with more doesn’t cut it anymore, just not good enough.

The behavior we’re looking for can be nicely described by the old TV game show Name That Tune, where two contestants competed to guess the name of a song with the fewest notes. They were read a clue that described a song, and ratcheted down the notes needed to guess it. Here’s the nugget: they challenged themselves to do more with less, they were excited to do more with less, they were rewarded when they did more with less. The smartest, most knowledgeable contestants needed fewer notes. Let me say that again – the best contestants used the fewest notes.

In product design, the number of notes is analogous to part count, but the similarities end there. Those that use the fewest are not considered our best or our most knowledgeable, they’re not rewarded for their work, and our organizations don’t create excitement or a sense of challenge around using the fewest.

For other work, the number of notes is analogous to complexity. Acknowledge those that use the fewest, because their impact ripples through your company, and makes all your work easier.

Pareto’s Three Lenses for Product Design

Axiom 1 – Time is short, so make sure you’re working on the most important stuff.

Axiom 1 – Time is short, so make sure you’re working on the most important stuff.

Axiom 2 – You can’t design out what you can’t see.

In product development, these two axioms can keep you out of trouble. They’re two sides of the same coin, but I’ll describe them one at a time and hope it comes together in the end.

With Axiom 1, how do you make sure you’re working on the most important stuff? We all know it’s function first – no learning there. But, sorry design engineers, it doesn’t end with function. You must also design for lean, for cost, and factory floor space. Great. More things to design for. Didn’t you say time was short? How the hell am I going to design for all that?

Now onto the seeing business of Axiom 2. If we agree that lean, cost, and factory floor space are the right stuff, we must “see it” if we are to design it out. See lean? See cost? See factory floor space? You’re nuts. How do you expect us to do that?

Pareto to the rescue – use Pareto charts to identify the most important stuff, to prioritize the work. With Pareto, it’s simple: work on the biggest bars at the expense of the smaller ones. But, Paretos of what?

There is no such thing as a clean sheet design – all new product designs have a lineage. A new design is based on an existing design, a baseline design, with improvements made in several areas to realize more features or better function defined by the product specification. The Pareto charts are created from the baseline design to allow you to see the things to design out (Axiom 2). But what lenses to use to see lean, cost, and factory floor space?

Here are Pareto’s three lenses so see what must be seen:

To lean out lean out your factory, design out the parts. Parts create waste and part count is the surrogate for lean.

To design out cost, measure cost. Cost is the surrogate for cost.

To design out factory floor space, measure assembly time. Since factory floor space scales with assembly time, assembly time is the surrogate for factory floor space.

Now that your design engineers have created the right Pareto charts and can see with the right glasses, they’re ready to focus their efforts on the most important stuff. No boiling the ocean here. For lean, focus on part count of subassembly 1; for cost, focus on the cost of subassemblies 2 and 4; for floor space, focus on assembly time of subassembly 5. Leave the others alone.

Focus is important and difficult, but Pareto can help you see the light.

Fasteners Can Consume 20-50% of Assembly Labor

The data-driven people in our lives tell us that you can’t improve what you can’t measure. I believe that. And it’s no different with product cost. Before improving product cost, before designing it out, you have to know where it is. However, it can be difficult to know what really creates cost. Not all parts and features are created equal; some create more cost than others, and it’s often unclear which are the heavy hitters. Sometimes the heavy hitters don’t look heavy, and often are buried deeply within the hidden factory.

The data-driven people in our lives tell us that you can’t improve what you can’t measure. I believe that. And it’s no different with product cost. Before improving product cost, before designing it out, you have to know where it is. However, it can be difficult to know what really creates cost. Not all parts and features are created equal; some create more cost than others, and it’s often unclear which are the heavy hitters. Sometimes the heavy hitters don’t look heavy, and often are buried deeply within the hidden factory.

Measure, measure, measure. That’s what the black belts say. However, it’s difficult to do well with product cost since our costing methods are hosed up and our measurement systems are limited. What do I mean? Consider fasteners (e.g., nuts, bolts, screws, and washers), the product’s most basic life form. Because fasteners are not on the BOM, they’re not part of product cost. Here’s the party line: it’s overhead to be shared evenly across all the products in a socialist way. That’s not a big deal, right? Wrong. Although fasteners don’t cost much in ones and twos, they do add up. 300-500 pieces per unit times the number of units per year makes for a lot of unallocated and untracked cost. However, a more significant issue with those little buggers is they take a lot of time attach to the product. For example, using standard time data from DFMA software, assembly of a 1/4″ nut with a bolt, locktite, a lockwasher, and cleanup takes 50 seconds. That’s a lot of time. You should be asking yourself what that translates to in your product. To figure it out, multiply the number nut/bolt/washer groupings by 50 seconds and multiply the result by the number of units per year. Actually, never mind. You can’t do the calculation because you don’t know the number of nut/bolt/washer combinations that are in your product. You could try to query your BOMs, but the information is likely not there. Remember, fasteners are overhead and not allocated to product. Have you ever tried to do a cost reduction project on overhead? It’s impossible. Because overhead inflicts pain evenly to all, no one is responsible to reduce it.

With fasteners, it’s like death by a thousand cuts.

The time to attach them can be as much as 20-50% of labor. That’s right, up to 50%. That’s like paying 20-50% of your folks to attach fasteners all day. That should make you sick. But it’s actually worse than that. From Line Design 101, the number of assembly stations is proportional to demand times labor time. Since fasteners inflate labor time, they also inflate the number of assembly stations, which, in turn, inflates the factory floor space needed to meet demand. Would you rather design out fasteners or add 15% to your floor space? I know you can get good deals on factory floor space due to the recession, but I’d still rather design out fasteners.

Even with the amount of assembly labor consumed by fasteners, our thinking and computer systems are blind to them and the associated follow-on costs. And because of our vision problems, the design community cannot be held accountable to design out those costs. We’ve given them the opportunity to play dumb and say things like, “Those fastener things are free. I’m not going to spend time worrying about that. It’s not part of the product cost.” Clearly not an enlightened statement, but it’s difficult to overcome without cost allocation data for the fasteners.

The work-around for our ailing thinking and computer-based cost tracking systems is simple: get the design engineers out to the production floor to build the product. Have them experience first hand how much waste is in the product. They’ll come back with a deep-in-the-gut understanding of how things really are. Then, have them use DFMA software to score the existing design, part-by-part, feature-by-feature. I guarantee everyone will know where the cost is after that. And once they know where the cost is, it will be easy for them to design it out.

I have data to support my assertion that fasteners can make up 20-50% of labor time, but don’t take my word for it. Go out to the factory floor, shut your eyes and listen. You’ll likely hear the never ending song of the nut runners. With each chirp, another nut is fastened to its bolt and washer, and another small bit of labor and factory floor space is consumed by the lowly fastener.

“Hyper” for Lean

“Hyper” for Lean — Lean Directions, SME

Hypertherm’s lean journey began in 1997 as a natural and enthusiastic extension of its long history of continuous improvement. Founded in 1968, the company’s “lean vision” includes training, application of 5S components, visual factory audits, single and mixed-model flow lines and the engagement of its product design functions.

A recent Hypertherm success is found in the company’s HyPerformance series of plasma arc, metalcutting systems. The company’s product design community designed a product line with Read the rest of this entry »

Mike Shipulski

Mike Shipulski