“Hyper” for Lean

“Hyper” for Lean — Lean Directions, SME

Hypertherm’s lean journey began in 1997 as a natural and enthusiastic extension of its long history of continuous improvement. Founded in 1968, the company’s “lean vision” includes training, application of 5S components, visual factory audits, single and mixed-model flow lines and the engagement of its product design functions.

A recent Hypertherm success is found in the company’s HyPerformance series of plasma arc, metalcutting systems. The company’s product design community designed a product line with Read the rest of this entry »

Allocating Responsibility for Manufacturing Cost

John Teresco of Industry Week wrote a thought-provoking article on assigning responsibility of product cost to the design engineering community (and not to the manufacturing community).

John Teresco of Industry Week wrote a thought-provoking article on assigning responsibility of product cost to the design engineering community (and not to the manufacturing community).

An expert from his article:

“We in the United States have mistakenly allocated the responsibility for [production] cost to the manufacturing folks. We forget that the cost has already been designed into the product.”

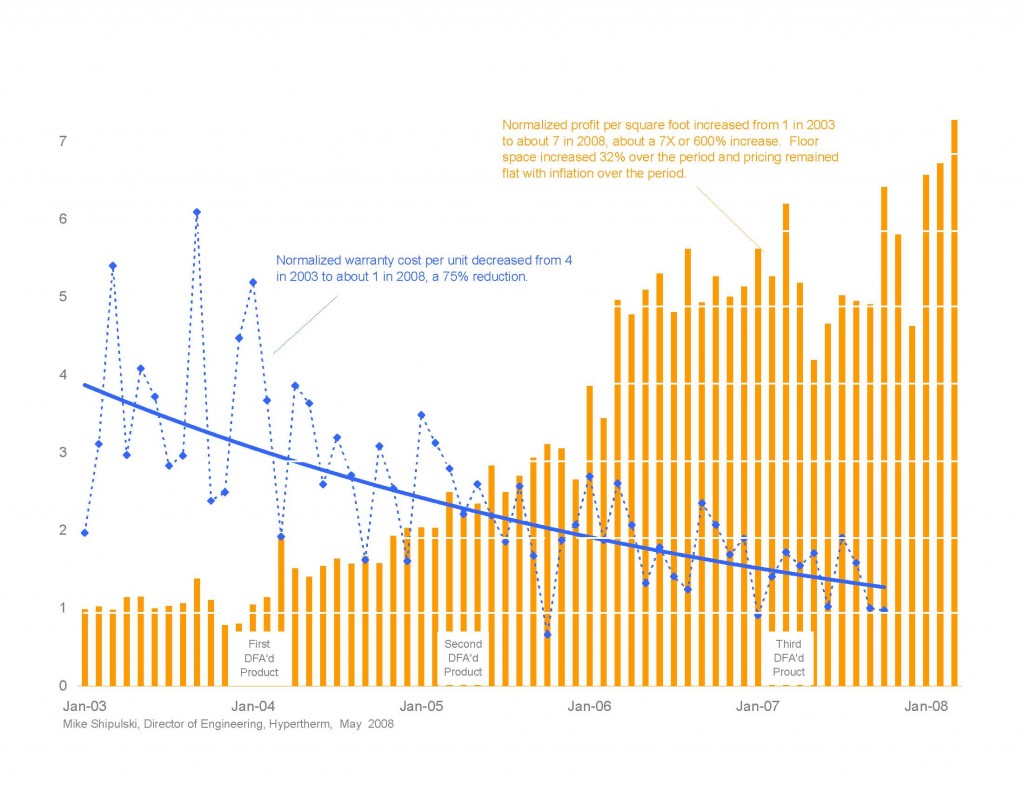

That’s Mike Shipulski, director of engineering with plasma cutting technology provider Hypertherm Inc., reflecting on one of the lessons learned from implementing Design for Manufacturing and Assembly (DFMA) software. The accomplishments include a 600% increase in profit per square foot of factory floor space within a five-year redesign program. Correspondingly, warranty cost per unit declined more than 75% during the same period, from January 2003 to January 2008.

Boothroyd Dewhurst DFMA Helps Slash Warranty Costs and Boost Factory Floor Profits 600 Percent at Hypertherm

Five-year implementation of DFMA software by Hypertherm creates higher profits and strong business model for improving U.S. global competitiveness

WAKEFIELD, R.I., and HANOVER, N.H.,USA, June 2, 2008—Hypertherm, the world leader in plasma metal cutting technology, has achieved a 600 percent increase in profit per square foot of factory floor space using Boothroyd Dewhurst, Inc., Design for Manufacture and Assembly (DFMA®) software within a five-year redesign program. Correspondingly, warranty cost per unit has declined more than 75 percent during that same period, from January 2003 to January 2008.

Measuring DFMA Savings

Wes Iverson, Managing Editor of Automation World, wrote a good artcle on DFMA’s ability to cut product cost, reduce part count, and save assembly floor space.

Measuring DFMA Savings — Automation World

An expert from his article:

When a Hypertherm team led by Shipulski designed a major new plasma cutting machine several years ago, the team was able to reduce the number of parts required to about 700, down from around 1,400 in the previous generation design. The result was a machine that took about four hours to build, compared to 10 hours for the previous unit, enabling Hypertherm to hit its 35 percent cost reduction target for the system.

What is a DFMA Culture?

What is a DFMA Culture? (.pdf, 1 page)

John Gilligan of Boothroyd Dewhurst, Inc. asked me to describe a DFMA culture. Here is my description:

At the highest level, a strong DFMA culture is founded on the understanding that The Product strongly governs most everything in a company. Product function governs what customers will pay for; product structure governs a company’s organizational structure; and product features, attributes and materials govern cost. Stepping down one level, the DFMA culture is founded on the understanding that product function and product cost are coupled – they are two sides of the same coin – and are considered together when doing DFMA. Read the rest of this entry »

Design for Manufacture and Assembly Helps OEM Reduce Warranty Costs, Boost Profits

Design2Part Magazine published a good article on DFMA’s ability to cut costs, labor, floor space and improve global competitiveness.

An expert from the article:

Five-year implementation of DFMA software creates strong business model for improving global competitiveness

“We started with a vision to make radical improvements in both product performance and product economies,” stated Mike Shipulski, Hypertherm’s director of engineering. “Hypertherm met both of these goals by aggressively applying Boothroyd Dewhurst’s software within our existing programs for robust design and lean manufacturing. We found their product simplification software made it easy for us to improve a product’s performance-to-cost ratio. Moreover, we learned that DFMA ideas and financial estimates also lead to profound savings beyond labor and part cost, creating a domino effect ‘downstream’ in operational areas of our organization.”

Successful Design For Assembly

Successful Design For Assembly

Each company works with design for assembly (DFA) methods for different reasons. Some companies want to take cost out of their products, some want to make more products in their factories, and some want to simplify the product to increase quality and reliability.

In a growing market, a company wants to reduce labor content to get more products through the factory and to meet demand without adding assembly workers. In a growing market, a company also wants to reduce the floor space required to meet demand without building another factory. Read the rest of this entry »

Free Up Floor Space with Design for Assembly and Part Count Reduction

Free Up Floor Space with Design for Assembly and Part Count Reduction

By Mike Shipulski, Director of Engineering, Hypertherm, Inc

Design for Assembly (DFA) methods have been around for over 25 years, but the number of companies using the methods is surprisingly low given that they are straight-forward, fast, and produce significant savings in traditional Value Added (VA) metrics: labor content and material cost. Now that LEAN has raised the world’s awareness of the importance of reducing Non-Value Added (NVA) activities, the true value of DFA methods can be appreciated.

As a first principle, Design for Assembly (DFA) methods focus on part count reduction. Part count reduction results in labor content reduction (fewer parts to assemble) and material cost reduction Read the rest of this entry »

Part Cutters – Design for assembly dramatically reduces complexity of plasma arc cutter, Joseph Ogando, Senior Editor, Design News

The engineers at Hypertherm Inc., a maker of plasma cutting systems,know a thing or two about cutting metals. They also know how to cut cost. A lot of cost. While redesigning one of the company’s best-selling plasma cutting systems, they managed to reduce parts’ count from more than 1,000 components to fewer than 500. System assembly time fell from 20 hours to less than five. And the output from the company’s existing assembly operation quadrupled — without any additional floor space or an expensive second shift. Bottom line: the redesign saved the company about $5 million in assembly costs over the past 24 months alone, according to Engineering Manager Mike Shipulski. Read the rest of this entry »

Six Lessons Learned from a Successful Design For Assembly Program

Six Lessons Learned DFA paper for May 2006 DFMA Forum.pdf (8 pages)

Each company works with Design for Assembly (DFA) methods for different reasons. Some companies want to take cost out of their products, some want to make more products in their factories, and some want to simplify the product to increase quality and reliability. In a growing market a company wants to reduce labor content to get more products through the factory to meet demand without adding assembly workers. And, in a growing market a company wants to reduce the required floor space required to meet demand without building another factory. Remarkably, the goals are similar for Read the rest of this entry »

Mike Shipulski

Mike Shipulski