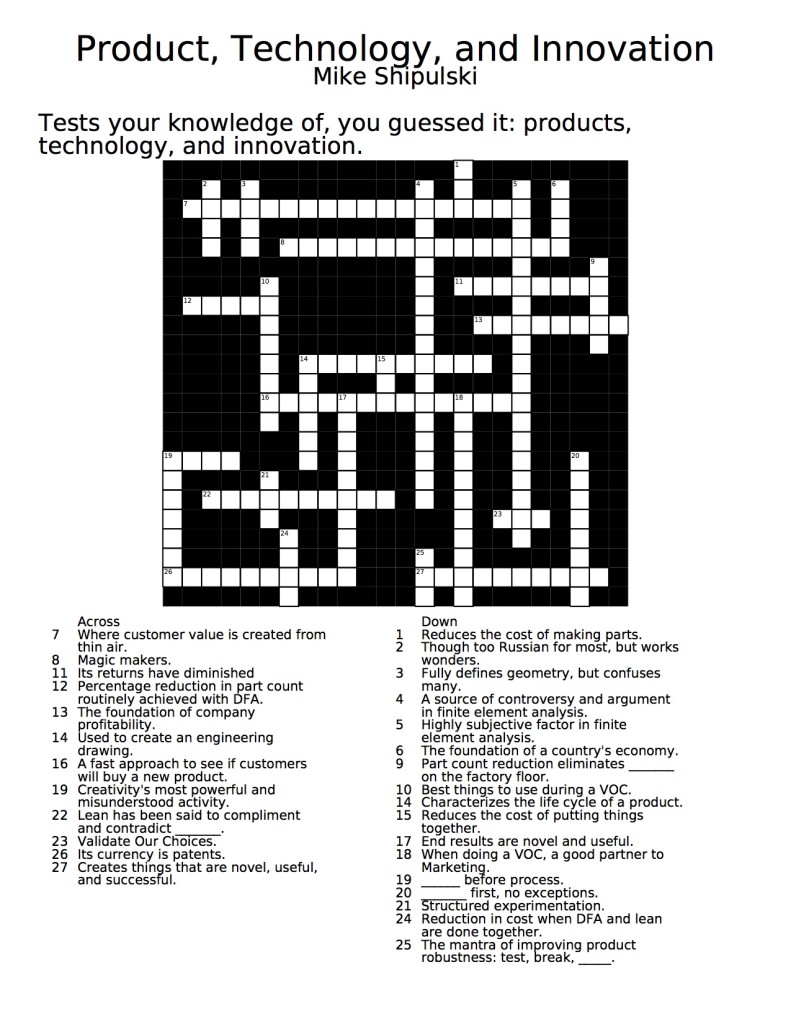

Crossword Puzzle – Product, Technology, Innovation

Here’s something a little different – a crossword puzzle to test your knowledge on products, technology, and innovation. Complete the puzzle using the image below, or download it (and answer key) using the green arrows below, and take your time with it over the Thanksgiving holiday.

[wpdm_file id=5]

[wpdm_file id=4]

Less Before More – Innovation’s Little Secret

The natural mindset of innovation is more-centric. More throughput; more performance; more features and functions; more services; more sales regions and markets; more applications; more of what worked last time. With innovation, we naturally gravitate toward more.

The natural mindset of innovation is more-centric. More throughput; more performance; more features and functions; more services; more sales regions and markets; more applications; more of what worked last time. With innovation, we naturally gravitate toward more.

There are two flavors of more, one better than the other. The better brother is more that does something for the first time. For example, the addition of the first airbags to automobiles – clearly an addition (previous vehicles had none) and clearly a meaningful innovation. More people survived car crashes because of the new airbags. This something-from-nothing more is magic, innovative, and scarce.

Most more work is of a lesser class – the more-of-what-is class. Where the first airbags were amazing, moving from eight airbags to nine – not so much. When the first safety razors replaced straight razors, they virtually eliminated fatal and almost fatal injuries, which was a big deal; but when the third and fourth blades were added, it was more trivial than magical. It was more for more’s sake; it was more because we didn’t know what else to do.

While more is more natural, less is more powerful. The Innovator’s Dilemma clearly called out the power of less. When the long-in-the-tooth S-curve flattens, Christensen says to look down, to look down and create technologies that do less. Actually, he tells us someone will give ground on the very thing that built the venerable S-curve to make possible a done-for-the-first-time innovation. He goes on to say you might as well be the one to dismantle your S-curve before a somebody else beats you to it. Yes, a wonderful way to realize the juciest innovation is with a less-centric mindset.

The LED revolution was made possible with less-centric thinking. As the incandescent S-curve hit puberty, wattage climbed and more powerful lights became cost effective; and as it matured, output per unit cost increased. More on more. And looking down from the graying S-curve was the lowly LED, whose output was far, far less.

But what the LED gave up in output it gained in less power draw and smaller size. As it turned out, there was a need for light where there had been none – in highly mobile applications where less size and weight were prized. And in these new applications, there was just a wisp of available power, and incandesent’s power draw was too much. If only there was a technology with less power draw.

But at the start, volumes for LEDs were far less than incandesent’s; profit margin was less; and most importantly, their output was far less than any self-respecting lightbulb. From on high, LEDs weren’t real lights; they were toys that would never amount to anything.

You can break intellectual inertia around more, and good things will happen. New design space is created from thin air once you are forced from the familiar. But it takes force. Creative use of constraints can help.

Get a small team together and creatively construct constraints that outlaw the goodness that makes your product great. The incandescent group’s constraint could be: create a light source that must make far less light. The automotive group’s constraint: create a vehicle that must have less range – battery powered cars. The smartphone group: create a smartphone with the fewest functions – wrist phone without Blutooth to something in your pocket , longer battery life, phone in the ear, phone in your eyeglasses.

Less is unnatural, and less is scary. The fear is your customers will get less and they won’t like it. But don’t be afraid because you’re going to sell to altogether different customers in altogether markets and applications. And fear not, because to those new customers you’ll sell more, not less. You’ll sell them something that’s the first of its kind, something that does more of what hasn’t been done before. It may do only a little bit of that something, but that’s far more than not being able to do it all.

Don’t tell anyone, but the next level of more will come from less.

Transplant Syndrome

Overall, our upward evolutionary spiral toward infinite productivity is a good thing. (More profit with less work – can’t argue with that.) And also good is our Darwinian desire to increase our chances of realizing profit by winding a thick cocoon of risk reduction around the work.

Overall, our upward evolutionary spiral toward infinite productivity is a good thing. (More profit with less work – can’t argue with that.) And also good is our Darwinian desire to increase our chances of realizing profit by winding a thick cocoon of risk reduction around the work.

But with our productivity helix comes a little known illness that’s rarely diagnosed. It’s not a full-fledged disease, rather, it’s a syndrome. It’s called Transplant Syndrome, or TS.

Along with general flu-like symptoms, TS produces a burning and itching desire to transplant something that worked well in one area into another. On its own, not a bad thing; the dangerous part of TS is that scratching its itch feels so good. And it feels so good because the scratching fits with capitalism’s natural law – only the most productive species will survive.

In a brain suffering from TS, transplanting Region A’s successful business model into Region B makes perfect productivity sense (No new thinking, but plenty of new revenue.) But that’s not the problem. The problem is the TS brain’s urge to transplant is insatiable and indiscriminate. With TS, along with Region B, it makes perfect sense to transplant into Region C, Region D, and Regions L, M, N, O, and P. And with TS, it must happen in record time. Like a parasite, TS feeds on our desire for productivity.

When you transplant your favorite flowering plant from one region of your yard to another, even the inexperienced gardener in us knows to question whether the new region will support the plant. Is the soil similar? Is there enough sun or too much? Will it be blocked from the wind like it is now? And because you know your yard (and because you asked the questions) you won’t transplant unless the viability threshold is met.

But what if you wanted to transplant your most precious flowering plant from your yard in North America to someone else’s yard in South America? At a high level, the viability questions are the same – sun, soil, and water, but the answers are hard to come by. Should you use google to get the answers? Should you get in an airplane and check the territory yourself? Should you talk to the local gardeners? (They don’t speak English.)

But digging deeper, there are many questions you don’t even know to ask. Some of the local bugs may eat your precious plant, so you better know the little crawlies by name and learn what they like to eat. But still, since the bugs have never seen your plant, you won’t know if they’ll eat it until they eat it. You can ask the local gardeners, but they won’t know. (They, too, have never seen it.) Or worse, they may treat it as invasive species and pull it out of the ground after you leave for home.

Here’s an idea. You could scout out local plants that look like yours and declare viability by similarity. But be careful because over the years the local plants have built up tacit defenses you can’t see.

Transplant Syndrome not just a business model syndrome; it infects broadly. In fact, there have been recent outbreaks reported in people that work with products, technologies, processes, and company cultures.

Unfortunately, there is no cure for TS. But, with the right prescription, symptoms can be managed.

Symptoms have been pushed into dormancy when companies hire the best, most experienced, local gardeners. These special gardeners must have been born and raised in-region. And in clinical trials the best results have been achieved when the chief gardener, a well respected local gardener in their own right, has full responsibility for designing, viability testing, and implementing the transplant program.

There have been reported cases of TS symptoms flaring up mid program, but in all cases there was a single common risk factor: no one listened to the gardeners on the receiving end of the transplant.

Choose Yourself

We’ve been conditioned to ask for direction; to ask for a plan; and ask for permission. But those ways no longer apply. Today that old behavior puts you at the front of the peloton in the great race to the bottom.

We’ve been conditioned to ask for direction; to ask for a plan; and ask for permission. But those ways no longer apply. Today that old behavior puts you at the front of the peloton in the great race to the bottom.

The old ways are gone.

Today’s new ways: propose a direction (better yet, test one out on a small scale); create and present a radical plan of your own (or better, on the smallest of scales test the novel aspects and present your learning); and demonstrate you deserve permission by initiating activity on something that will obsolete the very thing responsible for your success.

People that wait for someone to give them direction are now a commodity, and with commodities it always ends in the death spiral of low cost providers putting each other out of business. As businesses are waist deep in proposals to double-down on what hasn’t worked and are choking on their flattened S-curves, there’s a huge opportunity for people that have the courage to try new things on their own. Today, if you initiate you’ll differentiate.

[This is where you say to yourself – I’ve already got too much on my plate, and I don’t have the time or budget to do more (and unsanctioned) work. And this is where I tell you your old job is already gone, and you might as well try something innovative. It’s time to grab the defibrillator and jolt your company out of its flatline. ]

It’s time to respect your gut and run a low cost, micro-experiment to test your laughable idea. (And because you’ll keep the cost low, no one will know when it doesn’t go as you thought. [They never do.]) It’s time for an underground meeting with your trusted band of dissidents to plan and run your pico-experiment that could turn your industry upside down. It’s time to channel your inner kindergartener and micro-test the impossible.

It’s time to choose yourself.

The Threshold Of Uncertainty

Our threshold for uncertainty is too low.

Our threshold for uncertainty is too low.

Early in projects, even before the first prototype is up and running, you know what the product must do, what it will cost, and, most problematic, when you’ll be done. Independent of work content, level of newness, and workloads, there’s no uncertainty in your launch date. It’s etched in stone and the consequences are devastating.

A zero tolerance policy on uncertainty forces irrational behavior. As soon as possible, engineering gets something running in the lab, and then doesn’t want to change it because there’s no time. The prototype is almost impossible to build and is hypersensitive to normal process variation, but these issues are not addressed because there’s no time. Everyone agrees it’s important to fix it, and agrees to fix it after launch, but that never happens because the next project is already late before it starts. And the death cycle repeats project after project.

The root cause of this mess is the mistaken porting of manufacturing’s zero uncertainly mindset into design. The thinking goes like this – lean and Six Sigma have achieved magical success in manufacturing by eliminating uncertainty, so let’s do it in product design and achieve similar results. This is a fundamental mistake as the domains are fundamentally different.

In manufacturing the same product is made day-in and day-out – no uncertainty; in product design no two product development efforts are the same and there’s lots of stuff that’s done for the first time – uncertainty by definition. In manufacturing there’s a revision controlled engineering drawing that defines the right answer (the geometry and the material) – make it like the picture and it’s all good; in product design the material is chosen from many candidates and the geometry is created from scratch – the picture is created from nothing. By definition there’s more inherent uncertainty in product design, and to tighten the screws and fix the launch date at the start is inappropriate.

Design engineers must feel like there’s enough time to try new things because new products that provide new functionality require new technologies, new materials, and new geometries. With new comes inherent uncertainty, but there are ways to manage it.

To hold the timeline, give on the specification and cost. Design as fast as you can until you run out of time then launch. The product won’t work as well as you’d like and it will cost more than you’d like, but you’ll hit the schedule. A good way to do this is to de-feature a subassembly to reduce design time, and possibly reduce cost. Or, reuse a proven subassembly to reduce design time – take a hit in cost, but hit the timeline. The general idea – hold schedule but flex on performance and cost.

It feels like sacrilege to admit that something’s got to give, but it’s the truth. You’ve seen how it goes when you edict (in no uncertain terms) that the timeline will be met and there’ll be no give on performance and cost. It hasn’t worked, and it won’t – the inherent uncertainty of product design won’t let it.

Accept the uncertainty; be one with it; and manage it. It’s the only way.

Accomplishments in 2013 (Year Four)

Accomplishments in 2013

- Fourth year of weekly blog posts without missing a beat or repeating a post. (251 posts in total.)

- Third year of daily tweets – 2,170 in all. (@mikeshipulski)

- Second year as Top 40 Innovation Bloggers (#12) – Innovation Excellence, the web’s top innovation site.

- Seventh consecutive year as Keynote Speaker at International Forum on DFMA.

- Fourth year of LinkedIn working group – Systematic DFMA Deployment.

- Third year writing a column for Assembly Magazine (6 more columns this year).

- Wrote a book — PRODUCT PROCESS PEOPLE – Designing for Change (Which my subscribers can download for free.)

Top 5 Posts

- What They Didn’t Teach Me In Engineering School — a reflection on my learning after my learning.

- Guided Divergence — balancing act of letting go and shaping the future.

- Innovation in 26 words — literally.

- Lasting Behavioral Change — easy to say, tough to do.

- Prototype The Unfamiliar — test early and often.

I look forward to a great year 5.

What Aren’t You Doing?

You’re busier than ever, and almost every day you’re asked to do more. And usually it’s more with less – must improve efficiency so you can do more of what you already do. We want you to take this on, but don’t drop anything.

Improving your efficiency is good, and it’s healthy to challenge yourself to do more, but there’s a whole other side to things – a non-efficiency-based approach, where instead of asking how can you do more things, it’s about how you can do things that matter more.

And from this non-efficiency-based framework, the question “What aren’t you doing?” opens a worm hole to a new universe, and in this universe meaning matters. In this universe “What aren’t you doing?” is really “What aren’t you doing that is truly meaningful to you?”

[But before I’m accused of piling on the work, even if it’s meaningful work, I’ll give you an idea to free up time do more things that matter. First, change your email settings to off-line mode so no new messages pop on your screen and interrupt you. In the morning manually send and receive your email and answer email for 30 minutes; do the same in the afternoon. This will force you to triage your email and force you to limit your time. This will probably free up at least an hour a day.]

Now we’ll step through a process to figure out the most important thing you’re not doing.

Here is a link to a template to help you with the process — Template – What Aren’t You Doing.

The first step is to acknowledge there are important things you’re not doing and make a list. They can be anything – a crazy project, a deeper relationship, personal development, an adventure, or something else.

To make the list, ask these questions:

I always wanted to ____________.

I always wished I could __________.

Write down your answers. Now run the acid test to make sure these things are actually meaningful. Ask yourself:

When I think of doing this thing, do I feel uncomfortable or or a little scared?

If they don’t make you a little uncomfortable, they’re not meaningful. Go back to the top and start over. For the ones that make you uncomfortable, choose the most important, enter it in the template, and move to the next step.

In the second step you acknowledge there’s something in the way. Ask yourself:

I can’t do my most meaningful thing because _______________.

Usually it’s about time, money, lack of company support, goes against the norm, or it’s too crazy. On the template write down your top two or three answers.

In the third step you transform from an external focus to an internal one, and acknowledge what’s in the way is you. (For the next questions you must temporarily suspend reality and your very real day-to-day constraints and responsibilities.) Ask yourself:

If I started my most meaningful thing tomorrow I would feel uncomfortable that ____________.

Write down a couple answers, then ask:

The reason I would feel uncomfortable about my most meaningful thing is because I __________. (Must be something about you.)

Write down one or two. Some example reasons: you think your past experiences predict the future; you’re afraid to succeed; you don’t like what people will think about you; or the meaningful stuff contradicts your sense of self.

Spend an hour a week on this exercise until you understand the reasons you’re not doing your most meaningful thing. Then, spend an hour a week figuring out how to overcome your reasons for not doing. Then, spend an hour a week, or more, doing your most meaningful thing.

Celebrating Four Years!

Today is a celebration – four years of Shipulski On Design!

Today is a celebration – four years of Shipulski On Design!

To celebrate, I’m introducing my new book — Product Process People – Designing for Change.

And as a gift, I’m offering for free (pdf format) to my subscribers. If you’re a subscriber, click below to download the pdf. If you’re not a subscriber and you want the book, simply subscribe to my blog (see the box on the right) and download the pdf. (It’s the honor system.)

[wpdm_file id=3] Download it, read it, and share it with all your friends. (They don’t have to subscribe because you do.)

I hope the book helps you have a meaningful discussion about the future.

And for me, to help spread the message, if you download it please share it.

Thanks for reading, and I look forward to a great year 5.

Mike

Positivity – The Endangered Species

There’s a lot of negativity around us. But it’s not upfront, unadulterated negativity; it’s behind-the-scenes, hunkering, almost translucent negativity. And it’s divisive.

This type of negativity is so pervasive it’s almost invisible. It’s everywhere; we have processes built around it; have organizations dedicated to it; and we use it daily to drive action.

Take continuous improvement for example. It has been a standard toolset and philosophy for making things better. Yet it’s founded on negativity. It’s not anti-people, anti-culture negativity. (In fact lean and Six Sigma go on their way to emphasize positive culture as a key foundation.) It’s subtle negativity that slowly grinds. Look at the language: reduce defects, eliminate waste, corrective action, tight feedback loops, and eliminate failure modes. There is a negative tint. It’s not in your face, but it’s there.

I’m an advocate of lean and I have advocated for Six Sigma, both of which have moved the needle. But there’s a minimization thread running through them. Both are about eliminating and reducing what is. Sure they have their place, but enough is enough. We need more of creating what isn’t, and bringing to life things that aren’t. We need more maximization.

Negativity has become natural, and positivity has become an endangered species. When there’s a crisis we all come together instinctively to eliminate the bad thing. Yet it’s fourth or fifth nature to come together spontaneously when things go well. Yes, sometimes we celebrate, but it’s the exception. And it’s certainly not our first instinct. (Actually, I don’t think we have a word for spontaneous amplification of positivity. Celebration is the closest word I know, but it’s not the right one.)

Negative feedback is good for processes and positive feedback is good for people. Processes like when their flaws are eliminated, and people like when their strengths are amplified. It’s negativity for processes, and positivity for people.

There should be a rebalancing of negativity and positivity. For every graph of defect reduction over time, there should be a sister plot of the number of good things that happened over time. For every failure mode and effects analysis there should be a fishbone of chart of strengths and the associated actions to amplify them.

It’s natural for us to count bad things and make them go away, and not so natural to count good things and multiply them. Take at the meeting agendas. My bet is there’s far more minimization than maximization.

I usually end my posts with some specific call to action or recommendation. But for this one I don’t have anything all that meaty. But I will tell you how I’m going to move forward. When I see good work, I’m going to publicly acknowledge it and send emails of praise to the manager of the folks who did the good stuff. I’m going to track the number of emails I send and each week increase the number by one. I’m going to schedule regular meetings where I can publicly praise people that display passion. And I’m going to create a control chart of the number of times I amplify positivity.

And most of all I will try to keep in front of me that everything we do is all about people, and with people positivity is powerful.

The One Thing To Believe In

I used to believe in control, now I believe in trust.

I used to believe in process, now I believe in judgment.

I used to believe in WHAT and HOW, now I believe in WHO and WHY.

I used to believe in organizational structure, now I believe in personal relationships.

I used to believe in best practices, now I believe in the judgment to choose the right practices.

I used to believe in shoring up weaknesses, now I believe in building on strengths.

I used to believe in closing the gap, now I believe in the preferential cowpath.

I used to believe in innovation, now I believe in inspiration.

I used to believe in corrective action, now I believe in passionate action.

I used to believe in top down, now I believe in the people that do the work.

I used to believe in going fast, now I believe in doing it right as the means to go fast.

I used to believe in the product development process, now I believe in the people executing it.

I used to believe the final destination, now I believe in the current location.

I used to believe in machines, now I believe in the people that run them.

I used to believe in technology, now I believe in the people developing it.

I used to believe in hierarchy, now I believe in personal responsibility.

But if there’s one thing to believe in, I believe in people.

Moving From Kryptonite To Spinach

With websites, e-books, old fashioned books, Twitter, LinkedIn, Facebook, and blogs, there’s a seemingly limitless flood of information on every facet of business. There are heaps on innovation, new product development, lean, sales and marketing, manufacturing, and strategy; and within each there are elements and sub elements that fan out with multiple approaches.

With websites, e-books, old fashioned books, Twitter, LinkedIn, Facebook, and blogs, there’s a seemingly limitless flood of information on every facet of business. There are heaps on innovation, new product development, lean, sales and marketing, manufacturing, and strategy; and within each there are elements and sub elements that fan out with multiple approaches.

With today’s search engines and bots to automatically scan the horizon, it’s pretty easy to find what you’re looking for especially as you go narrow and deep. If you want to find best practices for reducing time-to-market for products designed in the US and manufactured in China, ask Google and she’ll tell you instantly. If you’re looking to improve marketing of healthcare products for the 20 to 40 year old demographic of the developing world, just ask Siri.

It’s now easy to separate the good stuff from the chaff and focus narrowly on your agenda. It’s like you have the capability dig into a box of a thousand puzzle pieces and pull out the very one you’re looking for. Finding the right puzzle piece is no longer the problem, the problem now is figuring out how they all fit together.

What holds the pieces together? What’s the common thread that winds through innovation, sales, marketing, and manufacturing? What is the backplane behind all this business stuff?

The backplane, and first fundamental, is product.

Every group has their unique work, and it’s all important – and product cuts across all of it. You innovate on product; sell product; manufacture product; service product. The shared context is the product. And I think there’s opportunity to use the shared context, this product lens, to open up design space of all our disciplines. For example how can the product change to make possible new and better marketing? How can the product change to radically simplify manufacturing? How can the product change so sales can tell the story they always wanted to tell? What innovation work must be done to create the product we all want?

In-discipline improvements have been good, but it’s time to take a step back and figure out how to create disruptive in-discipline innovations; to eliminate big discontinuities that cut across disciplines; and to establish multidisciplinary linkages and alignment to power the next evolution of our businesses. New design space is needed, and the product backplane can help.

Use the product lens to look along the backplane and see how changes in the product can bridge discontinuities across sales, marketing, and engineering. Use the common context of product to link revolutionary factory simplification to changes in the product. Use new sensors in the product to enable a new business model based on predictive maintenance. Let your imagination guide you.

It’s time to see the product for more than what it does and what it looks like. It’s time to see it as Superman’s kryptonite that constrains and limits all we do that can become Popeye’s spinach that can strengthen us to overpower all obstacles.

Mike Shipulski

Mike Shipulski