Archive for the ‘Technology’ Category

The Trust Network II

I stand by my statement that trust is the most important element in business (see The Trust Network.)

I stand by my statement that trust is the most important element in business (see The Trust Network.)

The Trust Network are the group of people who get the work done. They don’t do the work to get promoted, they just do the work because they like doing the work. They don’t take others’ credit (they’re not striving,) they just do the work. And they help each other do the work because, well, it’s the right thing to do.

Sometimes, they use their judgement to protect the company from bad ideas. But to be clear, they don’t protect the Status Quo. They use their good judgement to decide if a new idea has merit, and if it doesn’t, they try to shape it. And if they can’t shape it, they block it. Their judgement is good because their mutual trust allows them to talk openly and honestly and listen to each other. And through the process, they come to a decision and act on it.

But there’s another side to the Trust Network. They also bring new ideas to the company.

Trying new things is scary, but the Trust Network makes it safe. When someone has a good idea, the Network positively reinforces the goodness of the idea and recommends a small experiment. And when one installment of positivity doesn’t carry the day, the Trust Network comes together to create the additional positivity need to grow the idea into an experiment.

To make it safe, the Trust Network knows to keep the experiment small. If the small experiment doesn’t go as planned, they know there will be no negative consequences. And if the experiment’s results do attract attention, they dismiss the negativity of failure and talk about the positivity of learning. And if there is no money to run the experiment, they scare it up. They don’t stop until the experiment is completed.

But the real power of the Trust Network shows its hand after the successful experiment. The toughest part of innovation is the “now what” part, where successful experiments go to die. Since no one thought through what must happen to convert the successful experiment to a successful product, the follow-on actions are undefined and unbudgeted and the validated idea dies. But the Trust Network knows all this, so they help the experimenter define the “then what” activities before the experiment is run. That way, the resources are ready and waiting when the experiment is a success. The follow-on activities happen as planned.

The Trust Network always reminds each other that doing new things is difficult and that it’s okay that the outcome of the experiment is unknown. In fact, they go further and tell each other that the outcome of the experiment is unknowable. Regardless of the outcome of the experiment, the Trust Network is there for each other.

To start a Trust Network, find someone you trust and trust them. Support their new ideas, support their experiments and support the follow-on actions. If they’re afraid, tell them to be afraid and run the experiment. If they don’t have the resources to run the experiment, find the resources for them. And if they’re afraid they won’t get credit for all the success, tell them to trust you.

And to grow your Trust Network, find someone else you trust and trust them. And, repeat.

Image credit — Rolf Dietrich Brecher

Four Questions to Choose Innovation Projects

It’s a challenge to prioritize and choose innovation projects. There are open questions on the technology, the product/service, the customer, the price and sales volume. Other than that, things are pretty well defined.

It’s a challenge to prioritize and choose innovation projects. There are open questions on the technology, the product/service, the customer, the price and sales volume. Other than that, things are pretty well defined.

But with all that, you’ve still go to choose. Here are some questions that may help in your selection process

Is it big enough? The project will be long, expensive and difficult. And if the potential increase in sales is not big enough, the project is not worth starting. Think (Price – Cost) x Volume. Define a minimum viable increase in sales and bound it in time. For example, the minimum incremental sales is twenty five million dollars after five years in the market. If the project does not have the potential to meet those criteria, don’t do the project. The difficult question – How to estimate the incremental sales five years after launch? The difficult answer – Use your best judgement to estimate sales based on market size and review your assumptions and predictions with seasoned people you trust.

Why you? High growth markets/applications are attractive to everyone, including the big players and the well-funded start-ups. How does your company have an advantage over these tough competitors? What about your company sets you apart? Why will customers buy from you? If you don’t have good answers, don’t start the project. Instead, hold the work hostage and take the time to come up with good answers. If you come up with good answers, try to answer the next questions. If you don’t, choose another project.

How is it different? If the new technology can’t distinguish itself over existing alternatives, you don’t have a project worth starting. So, how is your new offering (the one you’re thinking about creating) better than the ones that can be purchased today? What’s the new value to the customer? Or, in the lingo of the day, what is the Distinctive Value Proposition (DVP)? If there’s no DVP, there’s no project. If you’re not sure of the DVP, figure that out before investing in the project. If you have a DVP but aren’t sure it’s good enough, figure out how to test the DVP before bringing the DVP to life.

Is it possible? Usually, this is where everyone starts. But I’ve listed it last, and it seems backward. Would you rather spend a year making it work only to learn no one wants it, or would you rather spend a month to learn the market wants it then a year making it work? If you make it work and no one wants it, you’ve wasted a year. If, before you make it work, you learn no one wants it, you’ve spent a month learning the right thing and you haven’t spent a year working on the wrong thing. It feels unnatural to define the market need before making it work, but though it feels unnatural, it can block resources from working on the wrong projects.

There is no foolproof way to choose the best innovation projects, but these four questions go a long way. Create a one-page template with four sections to ask the questions and capture the answers. The sections without answers define the next work. Define the learning objectives and the learning activities and do the learning. Fill in the missing answers and you’re ready to compare one project to another.

Sort the projects large-to-small by Is it big enough? Then, rank the top three by Why you? and How is it different? Then, for the highest ranked project, do the work to answer Is it possible?

If it’s possible, commercialize. If it’s not, re-sort the remaining projects by Is it big enough? Why you? and How is it different? and learn if It is possible.

Image credit – Ben Francis

Defy success and choose innovation.

Innovation is difficult because it requires novelty. And novelty is difficult because it’s different than last time. And different than last time is difficult because you’ve got to put yourself out there. And putting yourself out there is difficult because no one wants to be judged negatively.

Innovation is difficult because it requires novelty. And novelty is difficult because it’s different than last time. And different than last time is difficult because you’ve got to put yourself out there. And putting yourself out there is difficult because no one wants to be judged negatively.

Success, no matter how small, reinforces what was done last time. There’s safety in doing it again. The return may be small, but the wheels won’t fall off. You may run yourself into the ground over time, but you won’t fail catastrophically. You may not reach your growth targets, but you won’t get fired for slowly destroying the brand. In short, you won’t fail this year, but you will create the causes and conditions for a race to the bottom.

Diminishing returns are real. As a system improves it becomes more difficult to improve. A ten percent improvement is more difficult every year and at some point, improvement becomes impossible. In that way, success doesn’t breed success, it breeds more effort for less return. And as that improvement per unit effort decreases, it becomes ever more important (and ever more difficult) to do something different (to innovate).

Paradoxically, success makes it more difficult to innovate.

Success brings profits that could fund innovation. But, instead, success brings the expectation of predictable growth. Last year we were successful and grew 10%. We know the recipe, so this year let’s grow 12%. We can do what we did last year, but do it more efficiently. A sound bit of logic, except it assumes the rules haven’t changed and that competitors haven’t improved. But rules and competitors always change, and, at some point the the same old recipe for success runs out of gas.

It’s time to do something new (to innovate) when the same old effort brings reduced results. That change in output per unit effort means the recipe is tiring and it’s time for a new one. But with a new approach comes unpredictability, and for those who demand predictability, a new approach is scary. Sure, the yearly trend of reduced return on investment should scare them more, but it doesn’t. The devil you know is less scary than the one you don’t. But, it shouldn’t be.

Calculate your revenue dollars per sales associate and plot it over time. If the metric is flat over the last three years, it was time to innovate three years ago. If it’s decreasing over the last three years, it was time to innovate six years ago.

If you wait to innovate until revenue per sales person is flat, you waited too long.

No one likes to be judged negatively, more than that, no one likes their company to collapse and lose their job. So, choose to do something new (to innovate) and choose the possibility of being judged. That’s much better than choosing to go out of business.

Image credit – Michel Rathwell

For innovation to flow, drive out fear.

The primary impediment to innovation is fear, and the prime directive of any innovation system should be to drive out fear.

A culture of accountability, implemented poorly, can inject fear and deter innovation. When the team is accountable to deliver on a project but are constrained to a fixed scope, a fixed launch date and resources, they will be afraid. Because they know that innovation requires new work and new work is inherently unpredictable, they rightly recognize the triple accountability – time, scope and resources – cannot be met. From the very first day of the project, they know they cannot be successful and are afraid of the consequences.

A culture of accountability can be adapted to innovation to reduce fear. Here’s one way. Keep the team small and keep them dedicated to a single innovation project. No resource sharing, no swapping and no double counting. Create tight time blocks with clear work objectives, where the team reports back on a fixed pitch (weekly, monthly). But make it clear that they can flex on scope and level of completeness. They should try to do all the work within the time constraints but they must know that it’s expected the scope will narrow or shift and the level of completeness will be governed by the time constraint. Tell them you believe in them and you trust them to do their best, then praise their good judgement at the review meeting at the end of the time block.

Innovation is about solving new problems, yet fear blocks teams from trying new things. Teams like to solve problems that are familiar because they have seen previous teams judged negatively for missing deadlines. Here’s the logic – we’d rather add too little novelty than be late. The team would love to solve new problems but their afraid, based on past projects, that they’ll be chastised for missing a completion date that’s disrespectful of the work content and level of novelty. If you want the team to solve new problems, give them the tools, time, training and a teacher so they can select different problems and solve them differently. Simply put – create the causes and conditions for fear to quietly slink away so innovation will flow.

Fear is the most powerful inhibitor. But before we can lessen the team’s fear we’ve got to recognize the causes and conditions that create it. Fear’s job is to keep us safe, to keep us away from situations that have been risky or dangerous. To do this, our bodies create deep memories of those dangerous or scary situations and creates fear when it recognizes similarities between the current situation and past dangerous situations. In that way, less fear is created if the current situation feels differently from situations of the past where people were judged negatively.

To understand the causes and conditions that create fear, look back at previous projects. Make a list of the projects where project members were judged negatively for things outside their control such as: arbitrary launch dates not bound by the work content, high risk levels driven by unjustifiable specifications, insufficient resources, inadequate tools, poor training and no teacher. And make a list of projects where team members were praised. For the projects that praised, write down attributes of those projects (e.g., high reuse, low technical risk) and their outcomes (e.g., on time, on cost). To reduce fear, the project team will bend new projects toward those attributes and outcomes. Do the same for projects that judged negatively for things outside the project teams’ control. To reduce fear, the future project teams will bend away from those attributes and outcomes.

Now the difficult parts. As a leader, it’s time to look inside. Make a list of your behaviors that set (or contributed to) causes and conditions that made it easy for the project team to be judged negatively for the wrong reasons. And then make a list of your new behaviors that will create future causes and conditions where people aren’t afraid to solve new problems in new ways.

Image credit — andrea floris

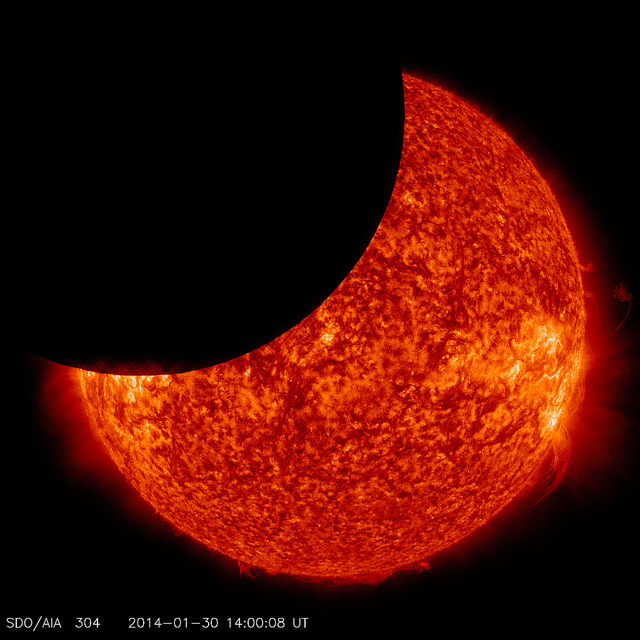

The right time horizon for technology development

Patents are the currency of technology and profits are the currency of business. And as it turns out, if you focus on creating technology you’ll get technology (and patents) and if you focus on profits you’ll get profits. But if no one buys your technology (in the form of the products or services that use it), you’ll go out of business. And if you focus exclusively on profits you won’t create technology and you’ll go out of business. I’m not sure which path is faster or more dangerous, but I don’t think it matters because either way you’re out of business.

Patents are the currency of technology and profits are the currency of business. And as it turns out, if you focus on creating technology you’ll get technology (and patents) and if you focus on profits you’ll get profits. But if no one buys your technology (in the form of the products or services that use it), you’ll go out of business. And if you focus exclusively on profits you won’t create technology and you’ll go out of business. I’m not sure which path is faster or more dangerous, but I don’t think it matters because either way you’re out of business.

It’s easy to measure the number of patents and easier to measure profits. But there’s a problem. Not all patents (technologies) are equal and not all profits are equal. You can have a stockpile of low-level patents that make small improvements to existing products/services and you can have a stockpile of profits generated by short-term business practices, both of which are far less valuable than they appear. If you measure the number of patents without evaluating the level of inventiveness, you’re running your business without a true understanding of how things really are. And if you’re looking at the pile of profits without evaluating the long-term viability of the engine that created them you’re likely living beyond your means.

In both cases, it’s important to be aware of your time horizon. You can create incremental technologies that create short term wins and consume all your resource so you can’t work on the longer-term technologies that reinvent your industry. And you can implement business practices that eliminate costs and squeeze customers for next-quarter sales at the expense of building trust-based engines of growth. It’s all about opportunity cost.

It’s easy to develop technologies and implement business processes for the short term. And it’s equally easy to invest in the long term at the expense of today’s bottom line and payroll. The trick is to balance short against long.

And for patents, to achieve the right balance rate your patents on the level of inventiveness.

Image credit – NASA’s Solar Dynamics Observatory

Choosing What To Do

In business you’ve got to do two things: choose what to do and choose how to do it well. I’m not sure which is more important, but I am sure there’s far more written on how to do things well and far less clarity around how to choose what to do.

In business you’ve got to do two things: choose what to do and choose how to do it well. I’m not sure which is more important, but I am sure there’s far more written on how to do things well and far less clarity around how to choose what to do.

Choosing what to do starts with understanding what’s being done now. For technology, it’s defining the state-of-the-art. For the business model, it’s how the leading companies are interacting with customers and which functions they are outsourcing and which they are doing themselves. In neither case does what’s being done define your new recipe, but in both cases it’s the first step to figuring how you’ll differentiate over the competition.

Every observation of the state-of-the-art technologies and latest business models is a snapshot in time. You know what’s happening at this instant, but you don’t know what things will look like in two years when you launch. And that’s not good enough. You’ve got to know the improvement trajectories; you’ve got to know if those trajectories will still hold true when you’ll launch your offering; and, if they’re out of gas, you’ve got to figure out the new improvement areas and their trajectories.

You’ve got to differentiate over the in-the-future competition who will constantly improve over the next two years, not the in-the-moment competition you see today.

For technology, first look at the competitions’ websites. For their latest product or service, figure out what they’re proud of, what they brag about, what line of goodness it offers. For example, is it faster, smaller, lighter, more powerful or less expensive? Then, look at the product it replaced and what it offered. If the old was faster than the one it replaced and the newest one was faster still, their next one will try to be faster. But if the old one was faster than the one it replaced and the newest one is proud of something else, it’s likely they’ll try to give the next one more of that same something else.

And the rate of improvement gives another clue. If the improvement is decreasing over time (old product to new product), it’s likely the next one will improve on a new line of goodness. If it’s still accelerating, expect more of what they did last time. Use the slope to estimate the magnitude of improvement two years from now. That’s what you’ve got to be better than.

And with business models, make a Wardley Map. On the map, place the elements of the business ecosystem (I hate that word) and connect the elements that interact with each other. And now the tricky part. Move to the right the mature elements (e.g., electrical power grid), move to the middle the immature elements (things that are clunky and you have to make yourself) and move to the middle the parts you can buy from others (products). There’s a north-south element to the maps, but that’s for another time.

The business model is defined by which elements the company does itself, which it buys from others and which new ones they create in their labs. So, make a model for each competitor. You’ll be able to see their business model visually.

Now, which elements to work on? Buy the ones you can buy (middle), improve the immature ones on the far left so they move toward the central region (product) and disrupt the lazy utilities (on the right) with some crazy technology development and create something new on the far left (get something running in the lab).

Choosing what to work on starts with Observation of what’s going on now. Then, that information is Oriented with analysis, synthesis and diverse perspective. Then, using the best frameworks you know, a Decision is made. And then, and only then, can you Act.

And there you have it. The makings of an OODA loop-based methodology for choosing what to do.

For a great podcast on John Boyd, the father of the OODA loop, try this one.

And for the deepest dive on OODA (don’t start with this one) see Osinga – Science, Strategy and War.

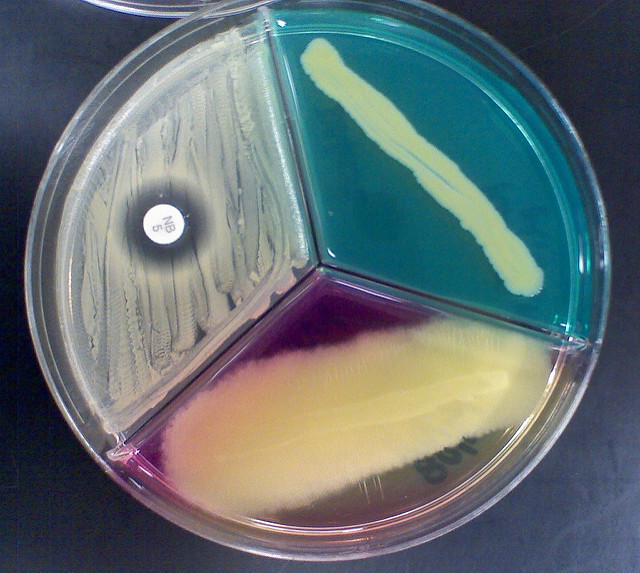

How to Avoid a Cliff

Much like living organisms continually evolve to secure their place in the future, technological systems can be thought to display similar evolutionary behavior. Viruses mutate so some of them can defeat the countermeasures of their host and live to fight another day. Technological systems, as an expression of a company’s desire to survive, evolve to defeat the competition and live to pay another dividend.

Much like living organisms continually evolve to secure their place in the future, technological systems can be thought to display similar evolutionary behavior. Viruses mutate so some of them can defeat the countermeasures of their host and live to fight another day. Technological systems, as an expression of a company’s desire to survive, evolve to defeat the competition and live to pay another dividend.

There are natural limits to evolutionary success in any single direction. When one trait is improved it pushes on the natural limits imposed by the environment. For example, a bacterium let loose in a friendly Petri dish will replicate until it eats all the food in the dish. Or, on a longer timescale, if the mass of a bird increases over generations when its food source is plentiful, the bird will get larger but will also get less agile. The predators who couldn’t catch the fast, little bird of old can easily catch and eat the sluggish heavyweight. In that way, there’s an edge condition created by the environmental Petri dishes and predators. And it’s the same with technological systems.

Companies and their technological systems evolve within their competitive environment by scanning the fitness landscape and deciding where to try to improve. The idea is to see preferential lines of improvement and create new technologies to take advantage of them. Like their smaller biological counterparts, companies are minimum energy creatures and want to maximize reward (profit) with minimum effort (expense) and will continue to leverage successful lines of evolution until it senses diminishing returns.

The diminishing returns are a warning sign that the company is approaching an edge condition (a Petri dish of a finite size). In landscape lingo, there’s a cliff on the horizon. In technology lingo, the rate of improvement of the technology is slowing. In either language, the edge is near and it’s time to evolve in a new direction because this current one is out of gas.

Like the bird whose mass increases over the generations when food is readily available, companies also get fat and slow when they successfully evolve in a single direction for too long. And like the bird, they get eaten by a more agile competitor/predator. And just as the replication rate of the bacterium accelerates as the food in the Petri dish approaches zero, a company that doesn’t react to a slowing rate of technological improvement is sure to outlive its business model.

Biology and technology are similar in that they try new things (create variants of themselves) in order to live another day. But there’s a big difference – where biology is blind (it doesn’t know what will work and what won’t), technology is sighted (people that create use their understanding to choose the variants they think will work best). And another difference is that biological evolution can build only on viable variants where technology can use mental models as scaffolds to skip non-viable embodiments to cross a chasm.

There’s no need to fall off the cliff. As a leading indicator, monitor the rate of improvement of your technology. If its rate of improvement is still accelerating, it’s time to develop the next line of evolution. If its rate is declining, you waited too long. It’s time to double down on two new lines of evolution because you’re behind the curve. And remember, like with the population of bacteria in the Petri dish, sales will keep growing right up until the business model runs out of food or a competitor eats you.

Image credit — Amanda

Technology, Technologists and Customers

Henry Ford famously said if he asked people what they wanted, they would have asked for faster horses. And there’s a lot of truth to his statement. If you ask potential customers what they want next, they’ll give you an answer. And when you show them the prototype, they won’t like it. Their intentions are good and their answers are truthful, but when you give them what they ask for and put the prototype in their hands, they will experience it in a way they did not expect. It will be different than they thought. Thinking how something will be is different than physically interacting with it. That’s how it is with new things.

Henry Ford famously said if he asked people what they wanted, they would have asked for faster horses. And there’s a lot of truth to his statement. If you ask potential customers what they want next, they’ll give you an answer. And when you show them the prototype, they won’t like it. Their intentions are good and their answers are truthful, but when you give them what they ask for and put the prototype in their hands, they will experience it in a way they did not expect. It will be different than they thought. Thinking how something will be is different than physically interacting with it. That’s how it is with new things.

And just like with the horses, because they don’t know the emergent technologies and their radically different capabilities, they can’t ask for what’s possible. They won’t ask for a combustion engine that eliminates their horses because all they know is horses. They’ll ask for more horses, bigger horses or smaller ones, but they won’t ask for combustion cylinders.

The trick is to understand what people do and why they do it. Like an anthropologist, spend time watching and understanding. And, if you can, understand what they don’t do and why they don’t do it. The new and deeper understanding of their actions, along with the reasons for them, create an anchoring perspective from which to understand how emergent technologies can change their lives.

Technologies evolve along worn paths. And depending on the maturity of the technology, some worth paths are more preferential than others. For example, if fuel economy is stagnant for the last ten years it means it’s likely time for a young technology to emerge that uses a different physical principle such as battery power. Though technology’s evolutionary direction is not predictable in an exact sense, it is dispositional. Like the meteorologist can’t pinpoint where the storm center will hit the coast or predict the maximum wind speed to within one or two miles per hour, she can say which states should hunker down and tell you if the wind will be strong enough to blow out your windows. She cannot predict the specifics, but she knows there’s a storm on the horizon and she knows its character, disposition and tendencies.

Now, anchored in how people use the state-of-the-art technologies (ride horseback, ride in buggies, use a team of horses to pull a heavy wagon) look at what the new technologies want to become (horses to combustion engine) and image how people’s lives would be better (faster trips, longer pleasure rides, heavier payloads, no barns and cleaner streets.) Now, using the new technology, build a prototype and show it to customers. Put them in the driver’s seat and blow their minds. Listen to the questions they ask so you can better understand the technology from their perspective because just as they don’t understand the technology, you don’t understand what the technology means to them, the people who will buy it. Use their questions to improve the technology and the product.

Technologists know technology, technology knows what it wants to be when it grows up and customers know what they want after they see what could be. And to create a new business, it takes all three working together.

Image credit — William Creswell

The Evolution of New Ideas

Before there is something new to see, there is just a good idea worthy of a prototype. And before there can be good ideas there are a whole flock of bad ones. And until you have enough self confidence to have bad ideas, there is only the status quo. Creating something from nothing is difficult.

Before there is something new to see, there is just a good idea worthy of a prototype. And before there can be good ideas there are a whole flock of bad ones. And until you have enough self confidence to have bad ideas, there is only the status quo. Creating something from nothing is difficult.

New things are new because they are different than the status quo. And if the status quo is one thing, it’s ruthless in desire to squelch the competition. In that way, new ideas will get trampled simply based on their newness. But also in that way, if your idea gets trampled it’s because the status quo noticed it and was threatened by it. Don’t look at the trampling as a bad sign, look at it as a sign you are on the right track. With new ideas there’s no such thing as bad publicity.

The eureka moment is a lie. New ideas reveal themselves slowly, even to the person with the idea. They start as an old problem or, better yet, as a successful yet tired solution. The new idea takes its first form when frustration overcomes intellectual inertia a strange sketch emerges on the whiteboard. It’s not yet a good idea, rather it’s something that doesn’t make sense or doesn’t quite fit.

The idea can mull around as a precursor for quite a while. Sometimes the idea makes an evolutionary jump in a direction that’s not quite right only to slither back to it’s unfertilized state. But as the environment changes around it, the idea jumps on the back of the new context with the hope of evolving itself into something intriguing. Sometimes it jumps the divide and sometimes it slithers back to a lower energy state. All this happens without conscious knowledge of the inventor.

It’s only after several mutations does the idea find enough strength to make its way into a prototype. And now as a prototype, repeats the whole process of seeking out evolutionary paths with the hope of evolving into a product or service that provides customer value. And again, it climbs and scratches up the evolutionary ladder to its most viable embodiment.

Creating something new from scratch is difficult. But, you are not alone. New ideas have a life force of their own and they want to come into being. Believe in yourself and believe in your ideas. Not every idea will be successful, but the only way to guarantee failure is to block yourself from nurturing ideas that threaten the status quo.

Image credit – lost places

A Barometer for Uncertainty

Novelty, or newness, can be a great way to assess the status of things. The level of novelty is a barometer for the level of uncertainty and unpredictability. If you haven’t done it before, it’s novel and you should expect the work to be uncertain and unpredictable. If you’ve done it before, it’s not novel and you should expect the work to go as it did last time. But like the barometer that measures a range of atmospheric pressures and gives an indication of the weather over the next hours, novelty ranges from high to low in small increments and so does the associated weather conditions.

Novelty, or newness, can be a great way to assess the status of things. The level of novelty is a barometer for the level of uncertainty and unpredictability. If you haven’t done it before, it’s novel and you should expect the work to be uncertain and unpredictable. If you’ve done it before, it’s not novel and you should expect the work to go as it did last time. But like the barometer that measures a range of atmospheric pressures and gives an indication of the weather over the next hours, novelty ranges from high to low in small increments and so does the associated weather conditions.

Barometers have a standard scale that measures pressure. When the summer air is clear and there are no clouds, the atmospheric pressure is high and on the rise and you should put on sun screen. When it’s hurricane season and super-low system approaches, the drops to the floor and you should evacuate. The nice thing about barometers is they are objective. On all continents, they can objectively measure the pressure and display it. No judgement, just read the scale. And regardless of the level of pressure and the number of times they measure it, the needle matches the pressure. No Kentucky windage. But novelty isn’t like that.

The only way to predict how things will go based on the level of novelty is to use judgement. There is no universal scale for novelty that works on all projects and all continents. Evaluating the level of novelty and predicting how the projects will go requires good judgement. And the only way to develop good judgment is to use bad judgment until it gets better.

All novelty isn’t created equal. And that’s the trouble. Some novelty has a big impact on the weather and some doesn’t. The trick is to know the difference. And how to tell the difference? If when you make a change in one part of the system (add novelty) and the novelty causes a big change in the function or operation of the system, that novelty is important. The system is telling you to use a light hand on the tiller. If the novelty doesn’t make much difference in system performance, drive on. The trick is to test early and often – simple tests that give thumbs-up or thumbs-down results. And if you try to run a test and you can’t get the test to run at all, there’s a hurricane is on the horizon.

When the work is new, you don’t really know which novelty will bite you. But there’s one rule: all novelty will bite you until proven otherwise. Make a list of the novel elements of the and test them crudely and quickly.

The Three Rs of Innovation – Risk, Reward, and Resources

Is it innovation or continuous improvement or is it innovation? Is it regular innovation or disruptive innovation? Is it new enough or too new? These questions are worse than meaningless as they suck emotional energy from the organization and divert emotional energy from the business objective.

Is it innovation or continuous improvement or is it innovation? Is it regular innovation or disruptive innovation? Is it new enough or too new? These questions are worse than meaningless as they suck emotional energy from the organization and divert emotional energy from the business objective.

With every initiative, there are risks, rewards, and resources. Risk generally tracks with newness, reward usually tracks with incremental customer goodness and resources are governed by the work. Risk is about the probability of tackling the newness, reward is about the size of the prize and resources are about how the work is done. There is no best amount of risk as sometimes the right amount is none and other times it’s more than everyone prefers. And there’s no best amount of reward as it depends on the company’s goals. And there’s no right amount of resources because there’s no right scope. For all three – risk, reward and resources – the right amount depends on the context.

For bottom line projects, it’s about maintaining product functionality while eliminating waste. And while there’s no right amount of risk, reward and resources, three filters (people, process, tools) can help get everyone on the same page.

Here are the escalating categories for people – no new people, move people from group A to group B, hire more people like the ones we have, hire new people with skills we don’t have. And for categories for process – no new processes, eliminate steps of existing processes, add steps to existing processes, create a process that’s new to the facility, create a process that’s new to the company, create process that’s new to the industry, create a process that’s new to the world. And for tools – no new tools, modify existing tools, buy new tools, create new tools from scratch.

There are no right answers, but if you’ve got to hire people you’ve never hired, create processes that are new-to-world, and invent new tools, it’s clear to everyone the project is pushing the envelope. And if the reward is significant and resources are plentiful, it could be a good way to go. And if there are no new hires, no new processes, and no new tools, don’t expect extravagant rewards. It’s not an exact science, but categorizing the newness in people, process, and tools and then comparing with the reward (payoff) makes clear any mismatches. And when mismatches are clear they can be managed. Resources can be added, the scope can be reduced and reward can be revisited.

For top line projects, it’s about providing novel usefulness to customers at a reasonable cost. And while risk, reward, and resources must be balanced, the filters are different. For top line, the filters are breadth of applicability, competition, is/isn’t.

Here are the escalating categories for breadth of applicability – same customer in the same application, same customers in a new application, new customers in a new market, new customers in different industry, new customers in an industry created by the project. For competition – many competitors in the same industry, fewer competitors in the same industry, fewer competitors in a different industry, no competitors (compete with no one.) And for is/isn’t – improve what is, radically improve what is, create what isn’t.

Again, no right answers. But the plan is to sell to the same customers into markets with the same powerful competitors with only a slight improvement to the existing product, don’t expect radical rewards and don’t run a project that consumes significant resources. And, if the plan is to create a whole new industry where there are no competitors and it requires an entirely new service that doesn’t yet exist, the potential reward should be spectacular, expect to allocate a boatload of resources and prepare for the project to take longer than expected or to be cancelled before completion.

Balancing risk, reward and resources is not an exact science. And the only way to get good at it is to calibrate new projects based on previous projects. To start the calibration process, try the process on your most recent completed projects. Categorize the projects with the relevant filters and define the resources consumed and the realized rewards. And when planning the next project, categorize with the filters and define the resource plan and planned rewards and see how they compare with the completed projects. And if there are mismatches, reconcile them with the realities of the previous projects.

Image credit – Ian Sane

Mike Shipulski

Mike Shipulski