Archive for the ‘Part Count Reduction’ Category

Resurrecting Manufacturing Through Product Simplification

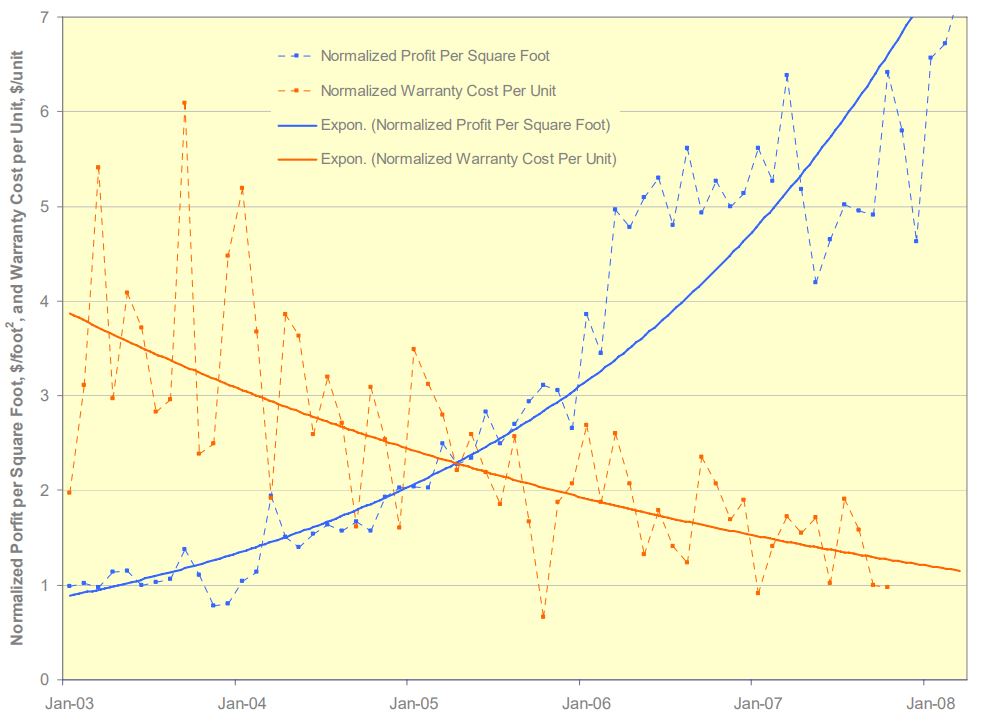

Product simplification can radically improve profits and radically improve product robustness. Here’s a graph of profit per square foot ($/ft^2) which improved by a factor of seven and warranty cost per unit ($/unit), a measure of product robustness), which improved by a factor of four. The improvements are measured against the baseline data of the legacy product which was replaced by the simplified product. Design for Assembly (DFA) was used to simplify the product and Robust Design methods were used to reduce warranty cost per unit.

I will go on record that everyone will notice when profit per square foot increases by a factor of seven.

And I will also go on record that no one will believe you when you predict product simplification will radically improve profit per square foot.

And I will go on record that when warranty cost per unit is radically reduced, customers will notice. Simply put, the product doesn’t break and your customers love it.

But here’s the rub. The graph shows data over five years, which is a long time. And if the product development takes two years, that makes seven long years. And in today’s world, seven years is at least four too many. But take another look at the graph. Profit per square foot doubled in the first two years after launch. Two years isn’t too long to double profit per square foot. I don’t know of a faster way, More strongly, I don’t know of another way to get it done, regardless of the timeline.

I think your company would love to double the profit per square foot of its assembly area. And I’ve shown you the data that proves it’s possible. So, what’s in the way of giving it a try?

For the details about the work, here’s a link – Systematic DFMA Deployment, It Could Resurrect US Manufacturing.

How Startups Can Move Prototypes Out Of The Lab And Onto The Factory Floor

Startups are good at making something work in the lab for the first time. However, startups are not good at moving their one-in-a-row prototypes to the manufacturing floor. But if startups are to scale, that’s exactly what they must do. For startups to be successful, they must continually change the design to enable the next level of production volume.

Startups are good at making something work in the lab for the first time. However, startups are not good at moving their one-in-a-row prototypes to the manufacturing floor. But if startups are to scale, that’s exactly what they must do. For startups to be successful, they must continually change the design to enable the next level of production volume.

To do that, I propose a 10, 100, 1000 approach.

After the one-in-a-row prototypes, how will you make 10? Can the crude assembly process produce 10 prototypes? If so, use the same crude assembly process. The cost of the prototypes is not a problem at this stage, so there’s no need to change the manufacturing processes to reduce the cost of the components. And at these low volumes, it’s unlikely the existing assembly process is too labor intensive (you’re only making 10) so there’s likely no need to change the process from a “time to build” perspective. But if the variation generated by the assembly process leads to prototypes that don’t function properly, the variation of the assembly process must be controlled with poke-yoke measures. Add only the controls you need because that work takes money and time which you don’t have as a startup. Otherwise, build the next 10 like you built the first one.

After the first 10, how will you make the next 100? Building 100 units doesn’t sound like a big deal, but 100 is a lot more than 10. Do you have suppliers who will sell you 100 of each part? Do you have the factory space to store the raw materials? Do you have the capability and capacity to inspect the incoming material? Do you have the money to buy all the parts? If the answer to all these questions is yes, it’s time to ask the difficult questions.

The cost of the units is likely still not a problem because the volumes are still small. There’s likely no need to change the manufacturing process (e.g., moving from machining to casting) to reduce the cost of the units. And it’s unlikely the time to build the units is becoming a problem because a super long build time isn’t all that problematic when building 100 units. So it’s not time to reduce the number of parts in the product (product simplification through part count reduction – aka, Design for Assembly). But it’s likely time to reduce the variation of the assembly process and eliminate the rework-inspect-test loop that comes when each unit that emerges from the production process is different. It’s time for assembly instructions, assembly fixtures, dedicated tools at each workstation, measurement tools to inspect the final product, and a group of quality professionals to verify the product is built correctly.

After the first 100, how will you make the next 1000? If you can, avoid changing the design, the manufacturing processes, or the assembly process. Keep everything the same and build 1000 units just as you built the first 100. But that’s unlikely because the cost will be too high and the assembly time will be too long. For the most expensive parts, consider changing the manufacturing process to one that can support higher volumes at a lower cost. You likely will have to buy the parts from another supplier who specializes in the new process and for that, you’ll need a purchasing professional with a quality background. To reduce build time, do Design for Assembly (DFA) to eliminate parts (fasteners and connectors). And for the processes that generate the highest rework times and scrap, add the necessary process controls to reduce variation and eliminate defects. Do the minimum (lowest investment dollars and design time) to achieve the appropriate cost and quality levels and declare success.

After 1000 units, it’s time to automate and move to new manufacturing processes. For the longest assembly processes, change the design (the parts themselves) to enable automated assembly processes. For the highest cost parts, change the parts (the design itself) to enable the move to manufacturing processes with lower cost signatures. The important idea is that the design and its parts must change to automate and enable lower-cost manufacturing processes. You’ll need new suppliers and purchasing professionals to bring them on board. You’ll need quality professionals to verify the quality of the incoming parts and the output of the assembly process. You’ll need manufacturing and automation engineers to simplify and automate the manufacturing processes.

The 10, 100, 1000 process is rather straightforward but it’s difficult because it requires judgement. At what production volume do you move to higher volume manufacturing processes to reduce costs? At what production volumes do you change the design to automate the assembly process to reduce assembly time? At what point do you add assembly fixtures to reduce variation? Which assembly processes do you improve and which do you leave as-is? When do you spend money on improvements and when do you buckle down and grind it out without making improvements?

The answer to all these questions is the same – hire a pro who has done it before. Hire a pro who knows when (and how) to do Design for Manufacturing and when to keep the design as it is. Hire a pro who knows when (and how) to add poke-yoke solutions and when to keep the assembly process as it is and rework the defects because that’s the lowest cost and fastest way to go. Hire a pro who knows when to change the design to reduce assembly time (Design for Assembly) and when to change the design and invest in automated assembly. Hire a pro who knows how (and when) to implement a full-blown quality system.

When it’s time to move from the lab to the factory floor, it’s time to hire a pro.

Image credit — Jim Roberts Gallery

Supply chains don’t have to break.

We’ve heard a lot about long supply chains that have broken down, parts shortages, and long lead times. Granted, supply chains have been stressed, but we’ve designed out any sort of resiliency. Our supply chains are inflexible, our products are intolerant to variation and multiple sources for parts, and our organizations have lost the ability to quickly and effectively redesign the product and the parts to address issues when they arise. We’ve pushed too hard on traditional costing and have not placed any value on flexibility. And we’ve pushed too hard on efficiency and outsourced our design capability so we can no longer design our way out of problems.

We’ve heard a lot about long supply chains that have broken down, parts shortages, and long lead times. Granted, supply chains have been stressed, but we’ve designed out any sort of resiliency. Our supply chains are inflexible, our products are intolerant to variation and multiple sources for parts, and our organizations have lost the ability to quickly and effectively redesign the product and the parts to address issues when they arise. We’ve pushed too hard on traditional costing and have not placed any value on flexibility. And we’ve pushed too hard on efficiency and outsourced our design capability so we can no longer design our way out of problems.

Our supply chains are inflexible because that’s how we designed them. The products cannot handle parts from multiple suppliers because that’s how we designed them. And the parts cannot be made by multiple suppliers because that’s how we designed them.

Now for the upside. If we want a robust supply chain, we can design the product and the parts in a way that makes a robust supply chain possible. If we want the flexibility to use multiple suppliers, we can design the product and parts in a way that makes it possible. And if we want the capability to change the product to adapt to unforeseen changes, we can design our design organizations to make it possible.

There are established tools and methods to help the design community design products in a way that creates flexibility in the supply chain. And those same tools and methods can also help the design community create products that can be made with parts from multiple suppliers. And there are teachers who can help rebuild the design community’s muscles so they can change the product in ways to address unforeseen problems with parts and suppliers.

How much did it cost you when your supply chain dried up? How much did it cost you the last time a supplier couldn’t deliver your parts? How much did it cost you when your design community couldn’t redesign the product to keep the assembly line running? Would you believe me if I told you that all those costs are a result of choices you made about how to design your supply chain, your product, your parts, and your engineering community?

And would you believe me if I told you could make all that go away? Well, even if you don’t believe me, the potential upside of making it go away is so significant you may want to look into it anyway.

Image credit — New Manufacturing Challenge, Suzaki, 1987.

Additive Manufacturing’s Holy Grail

The holy grail of Additive Manufacturing (AM) is high volume manufacturing. And the reason is profit. Here’s the governing equation:

The holy grail of Additive Manufacturing (AM) is high volume manufacturing. And the reason is profit. Here’s the governing equation:

(Price – Cost) x Volume = Profit

The idea is to sell products for more than the cost to make them and sell a lot of them. It’s an intoxicatingly simple proposition. And as long as you look only at the volume – the number of products sold per year – life is good. Just sell more and profits increase. But for a couple reasons, it’s not that simple. First, volume is a result. Customers buy products only when those products deliver goodness at a reasonable price. And second, volume delivers profit only when the cost is less than the price. And there’s the rub with AM.

Here’s a rule – as volume increases, the cost of AM is increasingly higher than traditional manufacturing. This is doubly bad news for AM. Not only is AM more expensive, its profit disadvantage is particularly troubling at high volumes. Here’s another rule – if you’re looking to AM to reduce the cost of a part, look elsewhere. AM is not a bottom-feeder technology.

If you want to create profits with AM, use it to increase price. Use it to develop products that do more and sell for more. The magic of AM is that it can create novel shapes that cannot be made with traditional technologies. And these novel shapes can create products with increased function that demand a higher price. For example, AM can create parts with internal features like serpentine cooling channels with fine-scale turbulators to remove more heat and enable smaller products or products that weigh less. Lighter automobiles get better fuel mileage and customers will pay more. And parts that reduce automobile weight are more valuable. And real estate under the hood is at a premium, and a smaller part creates room for other parts (more function) or frees up design space for new styling, both of which demand a higher price.

Now, back to cost. There’s one exception to cost rule. AM can reduce total product cost if it is used to eliminate high cost parts or consolidate multiple parts into a single AM part. This is difficult to do, but it can be done. But it takes some non-trivial cost analysis to make the case. And, because the technology is relatively new, there’s some aversion to adopting AM. An AM conversion can require a lot of testing and a significant cost reduction to take the risk and make the change.

To win with AM, think more function AND consolidation. More (or new) function to support a higher price (and increase volume) and reduced cost to increase profit per part. Don’t do one or the other. Do both. That’s what GE did with its AM fuel nozzle in their new aircraft engines. They combined 20 parts into a single unit which weighed 25 percent less than a traditional nozzle and was more than five times as durable. And it reduced fuel consumption (more function, higher price).

AM is well-established in prototyping and becoming more established in low-volume manufacturing. The holy grail for AM – high volume manufacturing – will become a broad reality as engineers learn how to design products to take advantage of AM’s unique ability to make previously un-makeable shapes and learn to design for radical part consolidation.

More function AND radical part consolidation. Do both.

Image credit – Les Haines

Product Thinking

Product costs, without product thinking, drop 2% per year. With product thinking, product costs fall by 50%, and while your competitors’ profit margins drift downward, yours are too high to track by conventional methods. And your company is known for unending increases in stock price and long term investment in all the things that secure the future.

The supply chain, without product thinking, improves 3% per year. With product thinking, longest lead processes are eliminated, poorest yield processes are a thing of the past, problem suppliers are gone, and your distributers associate your brand with uninterrupted supply and on time delivery.

Product robustness, without product thinking, is the same year-on-year. Re-injecting long forgotten product thinking to simplify the product, product robustness jumps to unattainable levels and warranty costs plummet. And your brand is known for products that simply don’t break.

Rolled throughput yield is stalled at 90%. With product thinking, the product is simplified, opportunities for defects are reduced, and throughput skyrockets due to improved RTY. And your brand is known as a good value – providing good, repeatable functionality at a good price.

Lean, without product thinking has delivered wonderful results, but the low hanging fruit is gone and lean is moving into the back office. With product thinking, the design is changed and value-added work is eliminated along with its associated non-value added work (which is about 8 times bigger); manufacturing monuments with their long changeover times are ripped out and sold to your competitors; work from two factories is consolidated into one; new work is taken on to fill the emptied factories; and profit per square foot triples. And your brand is known for best-in-class quality, unbeatable on time delivery, world class performance, and pioneering the next generation of lean.

The sales argument is low price and good payment terms. With product thinking, the argument starts with product performance and ends with product reliability. The sales team is energized, and your brand is linked with solid products that just plain work.

The marketing approach is stickers and new packaging. With product thinking, it’s based on competitive advantage explained in terms of head-to-head performance data and a richer feature set. And your brand stands for winning technology and killer products.

Product thinking isn’t for everyone. But for those that try – your brand will thank you.

Fix The Economy – Connect The Engineer To The Factory

Rumor has it, manufacturing is back. Yes, manufacturing jobs are coming back, but they’re coming back in dribbles. (They left in a geyser, so we still have much to do.) What we need is a fire hose of new manufacturing jobs.

Rumor has it, manufacturing is back. Yes, manufacturing jobs are coming back, but they’re coming back in dribbles. (They left in a geyser, so we still have much to do.) What we need is a fire hose of new manufacturing jobs.

Manufacturing jobs are trickling back from low cost countries because companies now realize the promised labor savings are not there and neither is product quality. But a trickle isn’t good enough; we need to turn the tide; we need the Mississippi river.

For flow like that we need a fundamental change. We need labor costs so low our focus becomes good quality; labor costs so low our focus becomes speed to market; labor costs so low our focus becomes speed to customer. But the secret is not labor rate. In fact, the secret isn’t even in the factory.

The secret is a secret because we’ve mistakenly mapped manufacturing solely to making (to factories). We’ve forgotten manufacturing is about designing and making. And that’s the secret: designing – adding product thinking to the mix. Design out the labor.

There are many names for designing and making done together. Most commonly it’s called concurrent engineering. Though seemingly innocuous, taken together, those words have over a thousand meanings layered with even more nuances. (Ask someone for a simple description of concurrent engineering. You’ll see.) It’s time to take a step back and demystify designing and making done together. We can do this with two simple questions:

- What behavior do we want?

- How do we get it?

What’s the behavior we want? We want design engineers to understand what drives cost in the factory (and suppliers’ factories) and design out cost. In short, we want to connect the engineer to the factory.

Great idea. But what if the factory and engineer are separated by geography? How do we get the behavior we want? We need to create a stand-in for the factory, a factory surrogate, and connect the engineer to the surrogate. And that surrogate is cost. (Cost is realized in the factory.) We get the desired behavior when we connect the engineer to cost.

When we make engineering responsible for cost (connect them to cost), they must figure out where the cost is so they can design it out. And when they figure out where the cost is, they’re effectively connected to the factory.

But the engineers don’t need to understand the whole factory (or supply chain), they only need to understand places that create cost (where the cost is.) To understand where cost is, they must look to the baseline product – the one you’re making today. To help them understand supply chain costs, ask for a Pareto chart of cost by part number for purchased parts. (The engineers will use cost to connect to suppliers’ factories.) The new design will focus on the big bars on the left of the Pareto – where the supply chain cost is.

To help them understand your factory’s cost, they must make two more Paretos. The first one is a Pareto of part count by major subassembly. Factory costs are high where the parts are – time to put them together. The second is a Pareto chart of process times. Factory costs are high where the time is – machine capacity, machine operators, and floor space.

To make it stick, use design reviews. At the first design review – where their design approach is defined – ask engineering for the three Paretos for the baseline product. Use the Pareto data to set a cost reduction goal of 50% (It will be easily achieved, but not easily believed.) and part count reduction goal of 50%. (Easily achieved.) Here’s a hint for the design review – their design approach should be strongly shaped by the Paretos.

Going forward, at every design review, ask engineering to present the three Paretos (for the new design) and cost and part count data (for the new design.) Engineering must present the data themselves; otherwise they’ll disconnect themselves from the factory.

To seal the deal, just before full production, engineering should present the go-to-production Paretos, cost, and part count data.

What I’ve described may not be concurrent engineering, but it’s the most profitable activity you’ll ever do. And, as a nice side benefit, you’ll help turn around the economy one company at a time.

Radically Simplify Your Value Stream – Change Your Design

The next level of factory simplification won’t come from your factory. It will come from outside your factory. The next level of simplification will come from upstream savings – your suppliers’ factories – and downstream savings – your distribution system. And this next level of simplification will create radically shorter value streams (from raw materials to customer.)

The next level of factory simplification won’t come from your factory. It will come from outside your factory. The next level of simplification will come from upstream savings – your suppliers’ factories – and downstream savings – your distribution system. And this next level of simplification will create radically shorter value streams (from raw materials to customer.)

To reinvent your value stream, traditional lean techniques – reduction of non-value added (NVA) time through process change – aren’t the best way. The best way is to eliminate value added (VA) time through product redesign – product change. Reduction of VA time generates a massive NVA savings multiple. (Value streams are mostly NVA with a little VA sprinkled in.) At first this seems like backward thinking (It is bit since lean focuses exclusively on NVA.), but NVA time exists only to enable VA time (VA work). No VA time, no associated NVA time.

Value streams are all about parts (making them, counting them, measuring them, boxing them, moving them, and un-boxing them) and products (making, boxing, moving.) The making – touch time, spindle time – is VA time and everything else is VA time. Design out the parts themselves (VA time) and NVA time is designed out. Massive multiple achieved.

But the design community is the only group that can design out the parts. How to get them involved? Not all parts are created equal. How to choose the ones that matter? Value streams cut across departments and companies. How to get everyone pulling together?

Watch the video: link to video. (And embedded below.)

A Recipe for Unreasonable Profits

There’s an unnatural attraction to lean – a methodology to change the value stream to reduce waste. And it’s the same with Design for Manufacturing (DFM) – a methodology to design out cost of your piece-parts. The real rain maker is Design for Assembly (DFA) which eliminates parts altogether (50% reductions are commonplace.) DFA is far more powerful.

There’s an unnatural attraction to lean – a methodology to change the value stream to reduce waste. And it’s the same with Design for Manufacturing (DFM) – a methodology to design out cost of your piece-parts. The real rain maker is Design for Assembly (DFA) which eliminates parts altogether (50% reductions are commonplace.) DFA is far more powerful.

The cost for a designed out part is zero. Floor space for a designed out part is zero. Transportation cost for a designed out part is zero. (Can you say Green?) From a lean perspective, for a designed out part there is zero waste. For a designed out part the seven wastes do not apply.

Here’s a recipe for unreasonable profits:

Design out half the parts with DFA. For the ones that remain, choose the three highest cost parts and design out the cost. Then, and only then, do lean on the manufacturing processes.

For a video version of the post, see this link: (Video embedded below.)

A Recipe for Unreasonable Profits.

Engineering’s Contribution to the Profit Equation

We all want to increase profits, but sometimes we get caught in the details and miss the big picture:

We all want to increase profits, but sometimes we get caught in the details and miss the big picture:

Profit = (Price – Cost) x Volume.

It’s a simple formula, but it provides a framework to focus on fundamentals. While all parts of the organization contribute to profit in their own way, engineering’s work has a surprisingly broad impact on the equation.

The market sets price, but engineering creates function, and improved function increases the price the market will pay. Design the product to do more, and do it better, and customers will pay more. What’s missing for engineering is an objective measure of what is good to the customer.

Pull the product lever, now.

If you’re reading this you’ve probably survived the great recession. You had to do some radical stuff, but you pulled it off. You cut to the bone as demand fell off, but you managed to shed staff and capacity and kept your company alive. Congratulations. Amazing work. But now the hard part: increased demand!

If you’re reading this you’ve probably survived the great recession. You had to do some radical stuff, but you pulled it off. You cut to the bone as demand fell off, but you managed to shed staff and capacity and kept your company alive. Congratulations. Amazing work. But now the hard part: increased demand!

Customers are ordering, and they want product now. You’re bringing on capacity, re-hiring, and re-training, and taking waste out of your processes with lean and even extending lean to your supply chain and logistics. You’re pulling the levers as hard as you can, but you know it won’t be enough. What you need is another lever, a big, powerful, magical lever to make everything better. You need to pull the product lever.

So, you’re telling me to look at my product as a way to meet increased demand? Yes. To get more products out of few factories? Yes. To make more products with a short staff? Yes. To reduce supply chain complexity? Yes. Pull the product lever, pull it hard, and pull it now.

But meeting increased demand is a manufacturing/supply chain problem, right? No. What about flogging suppliers for unreasonably short lead times? No. What about quickly bringing on unproven suppliers? No. What about bringing on a totally new factory by next week? No. What about using folks of the street to make the product? No. Pull the product lever, pull hard, and pull it now.

Dust off the value stream map of your supply chain and identify the three longest lead times, and design them out of your product. Dust off your routings and identify the three largest labor times, and design them out of our product. Dust off your BOMs and identify the three highest cost parts, and design them out of your product. Pull the product lever. Then, identify the next three, and pull it again. Then repeat. Pull it hard, and pull it now.

Meeting increased demand will be challenging, but your customers and stockholders deserve your best. So, pull hard on all your levers, and pull them now.

Too afraid to make money and create jobs.

What if you could double your factory throughput without adding people?

What if you could double your factory throughput without adding people?

What if you could reduce your product costs by 50%?

How much money would you make?

How many jobs would you create?

Why aren’t you doing it?

What are you afraid of?

Mike Shipulski

Mike Shipulski