Archive for the ‘Lean’ Category

Resurrecting Manufacturing Through Product Simplification

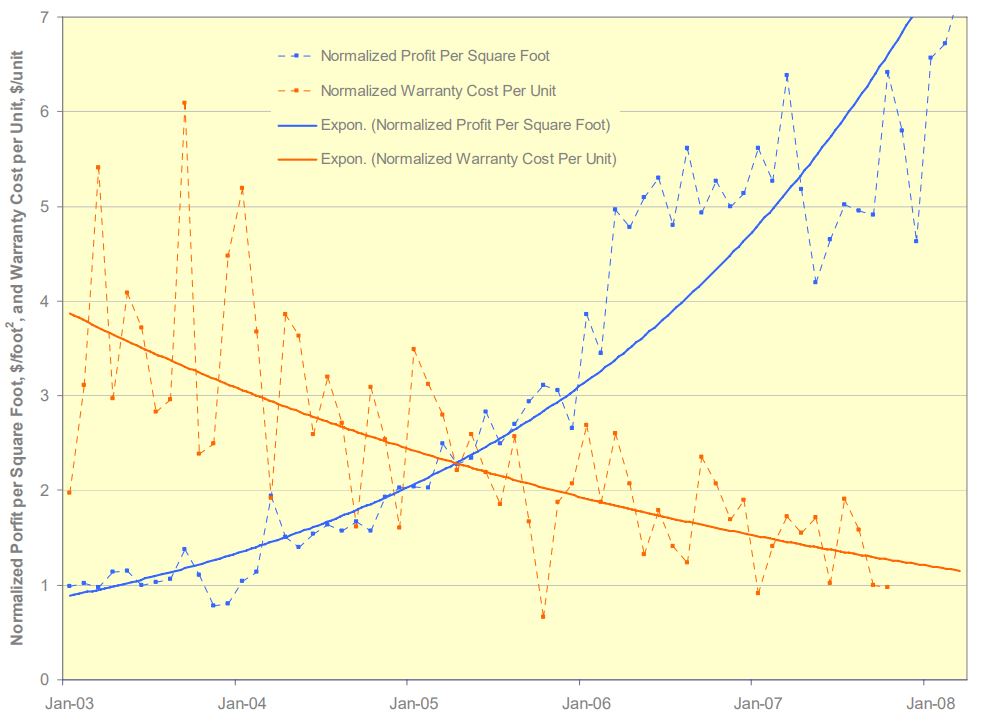

Product simplification can radically improve profits and radically improve product robustness. Here’s a graph of profit per square foot ($/ft^2) which improved by a factor of seven and warranty cost per unit ($/unit), a measure of product robustness), which improved by a factor of four. The improvements are measured against the baseline data of the legacy product which was replaced by the simplified product. Design for Assembly (DFA) was used to simplify the product and Robust Design methods were used to reduce warranty cost per unit.

I will go on record that everyone will notice when profit per square foot increases by a factor of seven.

And I will also go on record that no one will believe you when you predict product simplification will radically improve profit per square foot.

And I will go on record that when warranty cost per unit is radically reduced, customers will notice. Simply put, the product doesn’t break and your customers love it.

But here’s the rub. The graph shows data over five years, which is a long time. And if the product development takes two years, that makes seven long years. And in today’s world, seven years is at least four too many. But take another look at the graph. Profit per square foot doubled in the first two years after launch. Two years isn’t too long to double profit per square foot. I don’t know of a faster way, More strongly, I don’t know of another way to get it done, regardless of the timeline.

I think your company would love to double the profit per square foot of its assembly area. And I’ve shown you the data that proves it’s possible. So, what’s in the way of giving it a try?

For the details about the work, here’s a link – Systematic DFMA Deployment, It Could Resurrect US Manufacturing.

Seeing What Isn’t There

It’s relatively straightforward to tell the difference between activities that are done well and those that are done poorly. Usually sub-par activities generate visual signals to warn us of their misbehavior. A bill isn’t paid, a legal document isn’t signed or the wrong parts are put in the box. Though the specifics vary with context, the problem child causes the work product to fall off the plate and make a mess on the floor.

It’s relatively straightforward to tell the difference between activities that are done well and those that are done poorly. Usually sub-par activities generate visual signals to warn us of their misbehavior. A bill isn’t paid, a legal document isn’t signed or the wrong parts are put in the box. Though the specifics vary with context, the problem child causes the work product to fall off the plate and make a mess on the floor.

We have tools to diagnose the fundamental behind the symptom. We can get to root cause. We know why the plate was dropped. We know how to define the corrective action and implement the control mechanism so it doesn’t happen again. We patch up the process and we’re up and running in no time. This works well when there’s a well-defined in place, when process is asked to do what it did last time, when the inputs are the same as last time and when the outputs are measured like they were last time.

However, this linear thinking works terribly when the context changes. When the old processes are asked to do new work, the work hits the floor like last time, but the reason it hits the floor is fundamentally different. This time, it’s not that an activity was done poorly. Rather, this time there’s something missing altogether. And this time our linear-thinker toolbox won’t cut it. Sure, we’ll try with all our Six Sigma might, but we won’t get to root cause. Six Sigma, lean and best practices can fix what’s broken, but none of them can see what isn’t there.

When the context changes radically, the work changes radically. New-to-company activities are required to get the new work done. New-to-industry tools are needed to create new value. And, sometimes, new-to-world thinking is the only thing that will do. The trick isn’t to define the new activity, choose the right new tool or come up with the new thinking. The trick is to recognize there’s something missing, to recognize there’s something not there, to recognize there’s a need for something new. Whether it’s an activity, a tool or new thinking, we’ve got to learn to see what’s not there.

Now the difficult part – how to recognize there’s something missing. You may think the challenging part is to figure out what’s needed to fill the void, but it isn’t. You can’t fill a hole until you see it as a hole. And once everyone agrees there’s a hole, it’s pretty easy to buy the shovels, truck in some dirt and get after it. But if don’t expect holes, you won’t see them. Sure, you’ll break your ankle, but you won’t see the hole for what it is.

If the work is new, look for what’s missing. If the problem is new, watch out for holes. If the customer is new, there will be holes. If the solution is new, there will be more holes.

When the work is new, you will twist your ankle. And when you do, grab the shovels and start to put in place what isn’t there.

Image credit – Tony Atler

Before you can make a million, you’ve got to make the first one.

With process improvement, the existing process is refined over time. With innovation, the work is new. You can’t improve a process that does not yet exist. Process creation, yes. Process improvement, no.

With process improvement, the existing process is refined over time. With innovation, the work is new. You can’t improve a process that does not yet exist. Process creation, yes. Process improvement, no.

Standard work, where the sequence of process steps has proven successful, is a pillar of the manufacturing mindset. In manufacturing, if you’re not following standard work, you’re not doing it right. But with innovation, when the work is done for the first time, there can be no standard work. In that way, if you’re following the standard work paradigm, you are not doing innovation.

In a well-established manufacturing process, problems are tightly scoped and constrained. There can be several ways to solve it and one of the ways is usually better than the others. Teams are asked to solve the problem three or four ways and explain the rationale for choosing one solution over the other. With innovation it’s different. There may not be a solution, never mind three. With innovation, it’s one-in-a-row solution. And the real problem is to decide which problem to solve. If you’re asked to use Fishbone diagrams to solve the problem three or four ways, you’re not doing innovation. Solve it one way, show a potential customer and decide what to do next.

With manufacturing and product development, it’s all about Gantt charts and hitting dates. The tasks have a natural precedence and all of them have been done before. There are branches in the plan, but behind them is clear if-then logic. With innovation, the first task is well-defined. And the second task – it depends on the outcome of the first. And completion dates? No way. If you can predict the completion date, you’re not doing innovation. And if you’re asked for a fully built-out Gantt chart, you’re in trouble because that’s a misguided request.

Systems in manufacturing can be complicated, with lots of moving parts. And the problems can be complicated. But given enough time, the experts can methodically figure it out. But with innovation, the systems can be complex, meaning they are not predictable. Sometimes parts of the system interact strongly with other parts and sometimes they don’t interact at all. And it’s not that they do one or the other, it’s that they do both. It’s like they have a will of their own, and, sometimes, they have a bad attitude. And if it’s a new system, even the basic rules of engagement are unknown, never mind the changing strength of the interactions. And if the system is incomplete and you don’t know it, linear thinking of the experts can’t solve it. If you’re using linear problem solving techniques, you’re not doing innovation.

Manufacturing is about making one thing a million times. Innovation is about choosing among the million possibilities and making one-in-a-row, and then, after the bugs are worked out, making the new thing a million times. But one-in-a-row must come first. If you can’t do it once, you can’t do it a million times, even with process improvement, standard work, Gantt charts and Fishbone diagrams.

Image credit jacinta lluch valero

Innovation isn’t a thing in itself.

Innovation isn’t a thing in itself, and it’s not something to bolster for the sake of bolstering.

Innovation isn’t a thing in itself, and it’s not something to bolster for the sake of bolstering.

Innovation creates things (products, services, business models) that are novel, useful and successful. It’s important to know which flavor to go after, but before that it’s imperative to formalize the business objective. Like lean or Six Sigma, innovation is a business methodology whose sole intention is to deliver on the business objective. The business objective is usually a revenue or profit goal, and success is defined by meeting the objective. Successful is all about meeting the business objective and successful is all about execution.

There are a lot of things that must come together for an innovation to be successful. For an innovative product here are the questions to answer: Can you make it, certify it, market it, sell it, distribute it, service it, reclaim it? As it happens, these are the same questions to answer for any new product. In that way, innovative products are not different. But because innovation starts with novel, with innovative products the answers can be different. For an innovative product there are more “no’s” and for each no there’s a reason that starts with a C: constraint, capacity, capability, competitor, cooperation, capital. And the business objective cannot be achieved with closing the gaps.

After successful, there’s useful. Like any work based on a solid marketing methodology, innovation must deliver usefulness to the customer. Innovation or not, strong marketing is strong marketing and strong marketing defines who the customer is, how they’ll use the new service, and how they’ll benefit – the valuable customer outcome (VCO.) But with an innovative service it’s more difficult to know who the customer is, how they’ll use the service and if they’ll pay for it. (That’s the price of novelty.) But in most other ways, an innovative service is no different than any other service. Both are successful because they deliver usefulness customers, those customers pay money for the usefulness and the money surpasses the business objective.

Innovation is different because of novelty, but only in degree. Continuous improvement projects have novelty. Usually, it’s many small changes consistently applied that add up to meaningful results, for example waste reduction, improved throughput and product quality. These projects have novelty, but the novelty is the sum of small steps, all of which stay close to known territory.

The next rung on the novelty ladder is discontinuous improvement which creates a large step change in goodness provided to the customer. (Think 3X improvement.) The high degree of novelty creates broader uncertainty. Will the customer be able to realize the goodness? Will the novelty be appealing to a set of yet-to-be-discovered customers? Will they pay for it? It is worth doing all that execution work? Will it cannibalize other products? The novelty is a strong divergence from the familiar and with it comes the upside of new customer goodness and the downside of the uncertainty.

The highest form of novelty is no-to-yes. No other product on the planet could do it before, but the new innovative one can. It has the potential to create new markets, but also has the potential to obsolete the business model. The sales team doesn’t know how to sell it, the marketers don’t know how to market it and the factory doesn’t know how to make it. There new technology is not as robust as it should be and the cost structure may never become viable. There’s no way to predict how competitors will respond, there’s no telling if it will pass the regulatory requirements. And to top it off, no one is sure who the customer is or if anyone will it. But, if it all comes together, this innovation will be a game-changer.

Innovation is the same as all the other work, except there’s more novelty. And with that novelty comes more upside and more uncertainty. With novelty, too much of a good thing isn’t wonderful. Sufficient novelty must be ingested to meet the business objective, and a bit more for the long term to stay out in front.

Be clear about business objectives, deliver usefulness to customers and use novelty to make it happen. And call it whatever you want.

Image credit – Agustin Rafael Reyes

The Illusion of Planning

Planning is important work, but it’s non-value added work. Short and sweet – planning is waste.

Lean has taught us waste should be reduced, and the best way to reduce waste from planning is to spend less time planning. (I feel silly writing that.) Lean has taught us to reduce batch size, and the best way to reduce massive batch size of the annual planning marathon is to break it into smaller sessions. (I feel silly writing that too.)

Unreasonable time constraints increase creativity. To create next year’s plan, allocate just one for the whole thing. (Use a countdown timer.) And, because batch size must be reduced, repeat the process monthly. Twelve hours of the most productive planning ever, and countless planning hours converted into value added work.

Defining the future state and closing the gap is not the way to go. The way to go is to define the current state (where you are today) and define how to move forward. Use these two simple rules to guide you:

- Do more of what worked.

- Do less of what didn’t.

Here’s an example process:

The constraint – no new hires. (It’s most likely the case, so start there.)

Make a list of all the projects you’re working on. Decide which to stop right now (the STOP projects) and which you’ll finish by the end of the month (the COMPLETED projects). The remaining projects are the CONTINUE projects, and, since they’re aptly named, you should continue them next month. Then, count the number of STOP and COMPLETED projects – that’s the number of START projects you can start next month.

If the sum of STOP and COMPLETED is zero, ask if you can hire anyone this month. If the answer is no, see you next month.

If the sum is one, figure out what worked well, figure out how to build on it, and define the START project. Resources for the START project should be the same as the STOP or COMPLETED project.

If the sum is two, repeat.

Now ask if you can hire anyone this month. If the answer is no, you’re done. If the answer is yes, define how many you can hire.

With your number in hand, and building on what worked well, figure out the right START project. Resources must be limited by the number of new hires, and the project can’t start until the new hire is hired. (I feel silly writing that, but it must be written.) Or, if a START project can’t be started, use the new resource to pile on to an important CONTINUE project.

You’re done for the month, so send your updated plan to your boss and get back to work.

Next month, repeat.

The process will evolve nicely since you’ll refine it twelve times per year.

Ultimately, planning comes down to using your judgment to choose the next project based on the resources you’re given. The annual planning process is truly that simple, it’s just doesn’t look that way because it’s spread over so many months. So, if the company tells its leaders how many resources they have, and trusts them to use good judgment, yearly planning can be accomplished in twelve hours per year (literally). And since the plan is updated monthly, there’s no opportunity for emergency re-planning, and it will always be in line with reality.

Less waste and improved quality – isn’t that what lean taught us?

The Threshold Of Uncertainty

Our threshold for uncertainty is too low.

Our threshold for uncertainty is too low.

Early in projects, even before the first prototype is up and running, you know what the product must do, what it will cost, and, most problematic, when you’ll be done. Independent of work content, level of newness, and workloads, there’s no uncertainty in your launch date. It’s etched in stone and the consequences are devastating.

A zero tolerance policy on uncertainty forces irrational behavior. As soon as possible, engineering gets something running in the lab, and then doesn’t want to change it because there’s no time. The prototype is almost impossible to build and is hypersensitive to normal process variation, but these issues are not addressed because there’s no time. Everyone agrees it’s important to fix it, and agrees to fix it after launch, but that never happens because the next project is already late before it starts. And the death cycle repeats project after project.

The root cause of this mess is the mistaken porting of manufacturing’s zero uncertainly mindset into design. The thinking goes like this – lean and Six Sigma have achieved magical success in manufacturing by eliminating uncertainty, so let’s do it in product design and achieve similar results. This is a fundamental mistake as the domains are fundamentally different.

In manufacturing the same product is made day-in and day-out – no uncertainty; in product design no two product development efforts are the same and there’s lots of stuff that’s done for the first time – uncertainty by definition. In manufacturing there’s a revision controlled engineering drawing that defines the right answer (the geometry and the material) – make it like the picture and it’s all good; in product design the material is chosen from many candidates and the geometry is created from scratch – the picture is created from nothing. By definition there’s more inherent uncertainty in product design, and to tighten the screws and fix the launch date at the start is inappropriate.

Design engineers must feel like there’s enough time to try new things because new products that provide new functionality require new technologies, new materials, and new geometries. With new comes inherent uncertainty, but there are ways to manage it.

To hold the timeline, give on the specification and cost. Design as fast as you can until you run out of time then launch. The product won’t work as well as you’d like and it will cost more than you’d like, but you’ll hit the schedule. A good way to do this is to de-feature a subassembly to reduce design time, and possibly reduce cost. Or, reuse a proven subassembly to reduce design time – take a hit in cost, but hit the timeline. The general idea – hold schedule but flex on performance and cost.

It feels like sacrilege to admit that something’s got to give, but it’s the truth. You’ve seen how it goes when you edict (in no uncertain terms) that the timeline will be met and there’ll be no give on performance and cost. It hasn’t worked, and it won’t – the inherent uncertainty of product design won’t let it.

Accept the uncertainty; be one with it; and manage it. It’s the only way.

Positivity – The Endangered Species

There’s a lot of negativity around us. But it’s not upfront, unadulterated negativity; it’s behind-the-scenes, hunkering, almost translucent negativity. And it’s divisive.

This type of negativity is so pervasive it’s almost invisible. It’s everywhere; we have processes built around it; have organizations dedicated to it; and we use it daily to drive action.

Take continuous improvement for example. It has been a standard toolset and philosophy for making things better. Yet it’s founded on negativity. It’s not anti-people, anti-culture negativity. (In fact lean and Six Sigma go on their way to emphasize positive culture as a key foundation.) It’s subtle negativity that slowly grinds. Look at the language: reduce defects, eliminate waste, corrective action, tight feedback loops, and eliminate failure modes. There is a negative tint. It’s not in your face, but it’s there.

I’m an advocate of lean and I have advocated for Six Sigma, both of which have moved the needle. But there’s a minimization thread running through them. Both are about eliminating and reducing what is. Sure they have their place, but enough is enough. We need more of creating what isn’t, and bringing to life things that aren’t. We need more maximization.

Negativity has become natural, and positivity has become an endangered species. When there’s a crisis we all come together instinctively to eliminate the bad thing. Yet it’s fourth or fifth nature to come together spontaneously when things go well. Yes, sometimes we celebrate, but it’s the exception. And it’s certainly not our first instinct. (Actually, I don’t think we have a word for spontaneous amplification of positivity. Celebration is the closest word I know, but it’s not the right one.)

Negative feedback is good for processes and positive feedback is good for people. Processes like when their flaws are eliminated, and people like when their strengths are amplified. It’s negativity for processes, and positivity for people.

There should be a rebalancing of negativity and positivity. For every graph of defect reduction over time, there should be a sister plot of the number of good things that happened over time. For every failure mode and effects analysis there should be a fishbone of chart of strengths and the associated actions to amplify them.

It’s natural for us to count bad things and make them go away, and not so natural to count good things and multiply them. Take at the meeting agendas. My bet is there’s far more minimization than maximization.

I usually end my posts with some specific call to action or recommendation. But for this one I don’t have anything all that meaty. But I will tell you how I’m going to move forward. When I see good work, I’m going to publicly acknowledge it and send emails of praise to the manager of the folks who did the good stuff. I’m going to track the number of emails I send and each week increase the number by one. I’m going to schedule regular meetings where I can publicly praise people that display passion. And I’m going to create a control chart of the number of times I amplify positivity.

And most of all I will try to keep in front of me that everything we do is all about people, and with people positivity is powerful.

Moving From Kryptonite To Spinach

With websites, e-books, old fashioned books, Twitter, LinkedIn, Facebook, and blogs, there’s a seemingly limitless flood of information on every facet of business. There are heaps on innovation, new product development, lean, sales and marketing, manufacturing, and strategy; and within each there are elements and sub elements that fan out with multiple approaches.

With websites, e-books, old fashioned books, Twitter, LinkedIn, Facebook, and blogs, there’s a seemingly limitless flood of information on every facet of business. There are heaps on innovation, new product development, lean, sales and marketing, manufacturing, and strategy; and within each there are elements and sub elements that fan out with multiple approaches.

With today’s search engines and bots to automatically scan the horizon, it’s pretty easy to find what you’re looking for especially as you go narrow and deep. If you want to find best practices for reducing time-to-market for products designed in the US and manufactured in China, ask Google and she’ll tell you instantly. If you’re looking to improve marketing of healthcare products for the 20 to 40 year old demographic of the developing world, just ask Siri.

It’s now easy to separate the good stuff from the chaff and focus narrowly on your agenda. It’s like you have the capability dig into a box of a thousand puzzle pieces and pull out the very one you’re looking for. Finding the right puzzle piece is no longer the problem, the problem now is figuring out how they all fit together.

What holds the pieces together? What’s the common thread that winds through innovation, sales, marketing, and manufacturing? What is the backplane behind all this business stuff?

The backplane, and first fundamental, is product.

Every group has their unique work, and it’s all important – and product cuts across all of it. You innovate on product; sell product; manufacture product; service product. The shared context is the product. And I think there’s opportunity to use the shared context, this product lens, to open up design space of all our disciplines. For example how can the product change to make possible new and better marketing? How can the product change to radically simplify manufacturing? How can the product change so sales can tell the story they always wanted to tell? What innovation work must be done to create the product we all want?

In-discipline improvements have been good, but it’s time to take a step back and figure out how to create disruptive in-discipline innovations; to eliminate big discontinuities that cut across disciplines; and to establish multidisciplinary linkages and alignment to power the next evolution of our businesses. New design space is needed, and the product backplane can help.

Use the product lens to look along the backplane and see how changes in the product can bridge discontinuities across sales, marketing, and engineering. Use the common context of product to link revolutionary factory simplification to changes in the product. Use new sensors in the product to enable a new business model based on predictive maintenance. Let your imagination guide you.

It’s time to see the product for more than what it does and what it looks like. It’s time to see it as Superman’s kryptonite that constrains and limits all we do that can become Popeye’s spinach that can strengthen us to overpower all obstacles.

Product Thinking

Product costs, without product thinking, drop 2% per year. With product thinking, product costs fall by 50%, and while your competitors’ profit margins drift downward, yours are too high to track by conventional methods. And your company is known for unending increases in stock price and long term investment in all the things that secure the future.

The supply chain, without product thinking, improves 3% per year. With product thinking, longest lead processes are eliminated, poorest yield processes are a thing of the past, problem suppliers are gone, and your distributers associate your brand with uninterrupted supply and on time delivery.

Product robustness, without product thinking, is the same year-on-year. Re-injecting long forgotten product thinking to simplify the product, product robustness jumps to unattainable levels and warranty costs plummet. And your brand is known for products that simply don’t break.

Rolled throughput yield is stalled at 90%. With product thinking, the product is simplified, opportunities for defects are reduced, and throughput skyrockets due to improved RTY. And your brand is known as a good value – providing good, repeatable functionality at a good price.

Lean, without product thinking has delivered wonderful results, but the low hanging fruit is gone and lean is moving into the back office. With product thinking, the design is changed and value-added work is eliminated along with its associated non-value added work (which is about 8 times bigger); manufacturing monuments with their long changeover times are ripped out and sold to your competitors; work from two factories is consolidated into one; new work is taken on to fill the emptied factories; and profit per square foot triples. And your brand is known for best-in-class quality, unbeatable on time delivery, world class performance, and pioneering the next generation of lean.

The sales argument is low price and good payment terms. With product thinking, the argument starts with product performance and ends with product reliability. The sales team is energized, and your brand is linked with solid products that just plain work.

The marketing approach is stickers and new packaging. With product thinking, it’s based on competitive advantage explained in terms of head-to-head performance data and a richer feature set. And your brand stands for winning technology and killer products.

Product thinking isn’t for everyone. But for those that try – your brand will thank you.

Guided Divergence

We’ve been sufficiently polluted by lean and Six Sigma, and it’s time for them to go.

We’ve been sufficiently polluted by lean and Six Sigma, and it’s time for them to go.

Masquerading as maximizers, these minimizers-in-sheep’s-clothing have done deep harm. Though Six Sigma is almost dead (it’s been irrelevant for some time now), it has made a lasting mark. Billed as a profit maximizer, it categorically rejects maximization. In truth, it’s a variation minimizer and difference reducer. If it deviates, Six Sigma cuts its head off. Certainly this has a place in process control, but not in thinking control. But that’s exactly what’s happened. Six Sigma minimization has slithered off the manufacturing floor and created a culture of convergence. If your thinking is different, Six Sigma will clip it for you.

Lean is worse. All the buzz around lean is about maximizing throughput, but it doesn’t do that. It minimizes waste. But far worse is lean’s standard work. Minimize the difference among peoples’ work; make them do it the same; make the factory the same, regardless of the continent. All good on the factory floor, but lean’s minimization mania has spread like the plague and created a culture of convergence in its wake. And that’s the problem – lean’s minimization-standardization mantra has created a culture of convergence. If your thinking doesn’t fit in, lean will stomp it into place.

We need maximization at the expense of minimization, and divergence before convergence. We need creativity and innovation. But with Six Sigmaphiles and lean zealots running the show, maximization is little understood and divergence is a swear.

First we must educate on maximization. Maximization creates something that had not existed, while minimization reduces what is. Where Six Sigma minimization converges on the known right answer, creativity and innovation diverge to define a new question. The acid test: if you’re improving something you’re minimizing; if you’re inventing something you’re maximizing.

Like with He Who Shall Not Be Named, it’s not safe to say “diverge” out loud, because if you do, the lean Dementors will be called to suck out your soul. But, don’t despair – the talisman of guided divergence can save you.

With guided divergence, a team is given a creatively constructed set of constraints and very little time (hours) to come up with divergent ideas. The constraints guide the creativity (on target), and the tight timeline limits the risk – a small resource commitment. (Though counterintuitive, the tight timeline also creates remarkable innovation productivity.) Done in sets, several guided divergence sessions can cover a lot of ground in little time.

And the focused/constrained nature of guided divergence appeals to our minimization bias, and makes it okay to try a little divergence. We feel safe because we’re deviating only a little and only for a short time.

Lean and Six Sigma have served us well, and they still have their place. (Except for Six Sigma.) But they must be barred from creativity sessions and front end innovation, because here, divergence carries the day.

Small Is Good, And Powerful

If lean has taught us anything, it’s smaller is better. Smaller machines, smaller factories, smaller teams, smaller everything.

If lean has taught us anything, it’s smaller is better. Smaller machines, smaller factories, smaller teams, smaller everything.

The famous Speaker of the House, Tip O’Neill, said all politics are local. He meant all action happens at the lowest levels (in the districts and neighborhoods), where everyone knows everyone, where the issues are well understood, and the fundamentals are not just talked about, they’re lived. It’s the same with manufacturing. But I’m not talking about local in the geography sense; I’m talking about the neighborhood sense. When manufacturing is neighborhood-local, it’s small, tight, focused and knowledgeable.

We mistakenly think about manufacturing strictly as the process of making things—it’s far more. In the broadest sense, manufacturing is everything: innovation, design, making and service. It’s this broad-sense manufacturing that will deliver the next economic revolution.

Previously, I described how big companies break themselves into smaller operating units. They recognize lean favors small, and they break themselves up for competitive advantage. They want to become a collective of small companies with the upside of small without of the downside of big. Yet with small companies, there’s an urge to be big.

Lean says smaller is better and more profitable. Lean says small companies have an advantage because they’re already small. Lean says small companies should stay small (neighborhood small) and be more of what they are.

Small companies have a size advantage. Their smaller scope improves focus and alignment. It’s easier to define the mission, communicate it, and work toward it. It’s easier to mobilize the neighborhood. It’s clearer when things go off track and easier to get things back on track. At the lowest level, smaller companies zero in on problems and fix them. At the highest, they align themselves with their mission. These are important advantages, but not the most important.

The real advantage is deep process knowledge. Smaller companies have less breadth and more depth, which allows them to focus energy on the work and develop deep process knowledge. Many large manufacturers have lost process knowledge over the years. Small companies tend to develop and retain more of it. We’ve forgotten the value of deep process knowledge, but as companies look for competitive advantage, its stock is rising.

Lean wants small companies to build on that strength. To take it to the next level, lean wants companies to think about manufacturing in the more-than-making sense and use that deep process knowledge to influence the product itself. Lean wants suppliers to inject their process knowledge into their customers’ product development process to radically reduce material cost and help the product sprint through the factory.

The ultimate advantage of deep process knowledge is realized when small companies use it to design products. It’s realized when people who know the process fundamentals work respectfully with their neighbors who design the product. The result is deeper process knowledge and a far more profitable product. Big companies like to work with smaller companies who can design and make.

Tip O’Neill and lean agree. All manufacturing is local. And this local nature drives a focus on the fundamentals and details. Being neighborhood-local is easier for small companies because their scope is smaller, which helps them develop and retain deep process knowledge.

Lean wants companies to be small—neighborhood-small. When small companies build on a foundation of deep process knowledge, sales grow. Lean wants sales growth, but it also wants companies to reduce their size in the neighborhood sense.

Mike Shipulski

Mike Shipulski