Archive for the ‘Clarity’ Category

The Courage To Speak Up

If you see things differently than others, congratulations. You’re thinking for yourself.

If you see things differently than others, congratulations. You’re thinking for yourself.

If you find yourself pressured into thinking like everyone else, that’s a sign your opinion threatens. It’s too powerful to be dismissed out-of-hand, and that’s why they want to shut you up.

If the status quo is angered by your theory, you’re likely onto something. Stick to your guns.

If your boss doesn’t want to hear your contrarian opinion, that’s because it cannot be easily dismissed. That’s reason enough to say it.

If you disagree in a meeting and your sentiment is actively dismissed, dismiss the dismisser. And say it again.

If you’re an active member of the project and you are not invited to the meeting, take it as a compliment. Your opinion is too powerful to defend against. The only way for the group-think to survive is to keep you away from it. Well done.

If your opinion is actively and repeatedly ignored, it’s too powerful to be acknowledged. Send a note to someone higher up in the organization. And if that doesn’t work, send it up a level higher still. Don’t back down.

If you look into the future and see a train wreck, set up a meeting with the conductor and tell them what you see.

When you see things differently, others will try to silence you and tell you you’re wrong. Don’t believe them. The world needs people like you who see things as they are and have the courage to speak the truth as they see it.

Thank you for your courage.

Image credit – Cristian V.

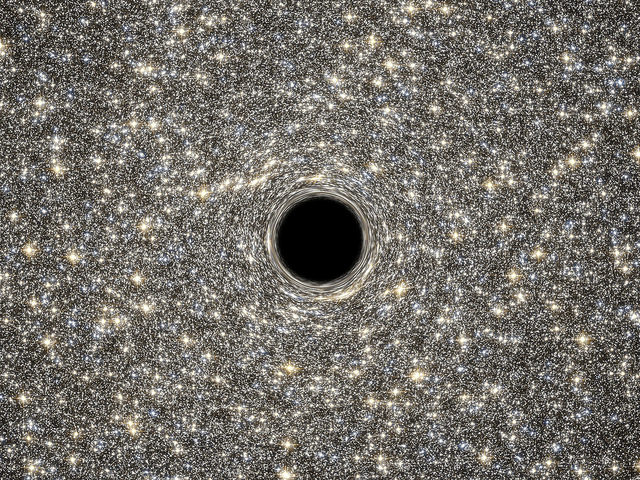

To figure out what’s next, define the system as it is.

Every day starts and ends in the present. Sure, you can put yourself in the future and image what it could be or put yourself in the past and remember what was. But, neither domain is actionable. You can’t change the past, nor can you control the future. The only thing that’s actionable is the present.

Every day starts and ends in the present. Sure, you can put yourself in the future and image what it could be or put yourself in the past and remember what was. But, neither domain is actionable. You can’t change the past, nor can you control the future. The only thing that’s actionable is the present.

Every morning your day starts with the body you have. You may have had a more pleasing body in the past, but that’s gone. You may have visions of changing your body into something else, but you don’t have that yet. What you do today is governed and enabled by your body as it is. If you try to lift three hundred pounds, your system as it is will either pick it up or it won’t.

Every morning your day starts with the mind you have. It may have been busy and distracted in the past and it may be calm and settled in the future, but that doesn’t matter. The only thing that matters is your mind as it is. If you respond kindly, today’s mind is responsible, and if your response is unkind, today’s mind system is the culprit. Like it or not, your thoughts, feelings and actions are the result of your mind as it is.

Change always starts with where you are, and the first step is unclear until you assess and define your systems as they are. If you haven’t worked out in five years, your first step is to see your doctor to get clearance (professional assessment) for your upcoming physical improvement plan. If you’ve run ten marathons over the last ten months, your first step may be to take a month off to recover. The right next step starts with where you are.

And it’s the same with your mind. If your mind is all over the place your likely first step is to learn how to help it settle down. And once it’s a little more settled, your next step may be to use more advanced methods to settle it further. And if you assess your mind and you see it needs more help than you can give it, your next step is to seek professional help. Again, your next step is defined by where you are.

And it’s the same with business. Every morning starts with the products and services you have. You can’t sell the obsolete products you had, nor can you sell the future services you may develop. You can only sell what you have. But, in parallel, you can create the next product or system. And to do that, the first step is to take a deep, dispassionate look at the system as it is. What does it do well? What does it do poorly? What can be built on and what can be discarded? There are a number of tools for this, but more important than the tools is to recognize that the next one starts with an assessment of the one you have.

If the existing system is young and immature, the first step is likely to nurture it and support it so it can grow out of its adolescence. But the first step is NOT to lift three hundred pounds because the system-as it is-can only lift fifty. If you lift too much too early, you’ll break its back.

If the existing system is in it’s prime and has been going to the gym regularly for the last five years, its ready for three hundred pounds. Go for it! But, in parallel, it’s time to start a new activity, one that will replace the weightlifting when the system can no longer lift like it used to. Maybe tennis? But start now because to get good at tennis requires new muscles and time.

And if the existing system is ready for retirement, retire it. Difficult to do, but once there’s public acknowledgement, the retirement will take care of itself.

If you want to know what’s next, define the system as it is. The next step will be clear.

And the best time to do it is now.

Image credit – NASA

Your response is your responsibility.

If you don’t want to go to work in the morning, there’s a reason. If’ you/re angry with how things go, there’s a reason. And if you you’re sad because of the way that people treat you, there’s a reason. But the reason has nothing to do with your work, how things are going or how people treat you. The reason has everything to do with your ego.

If you don’t want to go to work in the morning, there’s a reason. If’ you/re angry with how things go, there’s a reason. And if you you’re sad because of the way that people treat you, there’s a reason. But the reason has nothing to do with your work, how things are going or how people treat you. The reason has everything to do with your ego.

And your ego has everything to do with what you think of yourself and the identity you attach to yourself. If you don’t want to go to work, it’s because you don’t like what your work says about you or your image of your self. If you are angry with how things go, it’s because how things go says something about you that you don’t like. And if you’re sad about how people treat you, it’s because you think they may be right and you don’t like what that says about you.

The work is not responsible for your dislike of it. How things go is not responsible for your anger. And people that treat you badly are not responsible for your sadness. Your dislike is your responsibility, your anger is your responsibility and your sadness is your responsibility. And that’s because your response is your responsibility.

Don’t blame the work. Instead, look inside to understand how the work cuts against the grain of who you think you are. Don’t blame the things for going as they go. Instead, look inside to understand why those things don’t fit with your self-image. Don’t blame the people for how they treat you. Instead, look inside to understand why you think they may be right.

It’s easy to look outside and assign blame for your response. It’s the work’s fault, it’s the things’ fault, and it’s the people’s fault. But when you take responsibility for your response, when you own it, work gets better, things go better and people treat you better. Put simply, you take away their power to control how you feel and things get better.

And if work doesn’t get better, things don’t go better and people don’t treat you better, not to worry. Their responses are their responsibility.

Image credit Mrs. Gemstone

Choosing What To Do

In business you’ve got to do two things: choose what to do and choose how to do it well. I’m not sure which is more important, but I am sure there’s far more written on how to do things well and far less clarity around how to choose what to do.

In business you’ve got to do two things: choose what to do and choose how to do it well. I’m not sure which is more important, but I am sure there’s far more written on how to do things well and far less clarity around how to choose what to do.

Choosing what to do starts with understanding what’s being done now. For technology, it’s defining the state-of-the-art. For the business model, it’s how the leading companies are interacting with customers and which functions they are outsourcing and which they are doing themselves. In neither case does what’s being done define your new recipe, but in both cases it’s the first step to figuring how you’ll differentiate over the competition.

Every observation of the state-of-the-art technologies and latest business models is a snapshot in time. You know what’s happening at this instant, but you don’t know what things will look like in two years when you launch. And that’s not good enough. You’ve got to know the improvement trajectories; you’ve got to know if those trajectories will still hold true when you’ll launch your offering; and, if they’re out of gas, you’ve got to figure out the new improvement areas and their trajectories.

You’ve got to differentiate over the in-the-future competition who will constantly improve over the next two years, not the in-the-moment competition you see today.

For technology, first look at the competitions’ websites. For their latest product or service, figure out what they’re proud of, what they brag about, what line of goodness it offers. For example, is it faster, smaller, lighter, more powerful or less expensive? Then, look at the product it replaced and what it offered. If the old was faster than the one it replaced and the newest one was faster still, their next one will try to be faster. But if the old one was faster than the one it replaced and the newest one is proud of something else, it’s likely they’ll try to give the next one more of that same something else.

And the rate of improvement gives another clue. If the improvement is decreasing over time (old product to new product), it’s likely the next one will improve on a new line of goodness. If it’s still accelerating, expect more of what they did last time. Use the slope to estimate the magnitude of improvement two years from now. That’s what you’ve got to be better than.

And with business models, make a Wardley Map. On the map, place the elements of the business ecosystem (I hate that word) and connect the elements that interact with each other. And now the tricky part. Move to the right the mature elements (e.g., electrical power grid), move to the middle the immature elements (things that are clunky and you have to make yourself) and move to the middle the parts you can buy from others (products). There’s a north-south element to the maps, but that’s for another time.

The business model is defined by which elements the company does itself, which it buys from others and which new ones they create in their labs. So, make a model for each competitor. You’ll be able to see their business model visually.

Now, which elements to work on? Buy the ones you can buy (middle), improve the immature ones on the far left so they move toward the central region (product) and disrupt the lazy utilities (on the right) with some crazy technology development and create something new on the far left (get something running in the lab).

Choosing what to work on starts with Observation of what’s going on now. Then, that information is Oriented with analysis, synthesis and diverse perspective. Then, using the best frameworks you know, a Decision is made. And then, and only then, can you Act.

And there you have it. The makings of an OODA loop-based methodology for choosing what to do.

For a great podcast on John Boyd, the father of the OODA loop, try this one.

And for the deepest dive on OODA (don’t start with this one) see Osinga – Science, Strategy and War.

A Little Uninterrupted Work Goes a Long Way

If your day doesn’t start with a list of things you want to get done, there’s little chance you’ll get them done. What if you spent thirty minutes to define what you want to get done and then spent an hour getting them done? In ninety minutes you’ll have made a significant dent in the most important work. It doesn’t sound like a big deal, but it’s bigger than big. Question: How often do you work for thirty minutes without interruptions?

If your day doesn’t start with a list of things you want to get done, there’s little chance you’ll get them done. What if you spent thirty minutes to define what you want to get done and then spent an hour getting them done? In ninety minutes you’ll have made a significant dent in the most important work. It doesn’t sound like a big deal, but it’s bigger than big. Question: How often do you work for thirty minutes without interruptions?

Switching costs are high, but we don’t behave that way. Once interrupted, what if it takes ten minutes to get back into the groove? What if it takes fifteen minutes? What if you’re interrupted every ten or fifteen minutes? Question: What if the minimum time block to do real thinking is thirty minutes of uninterrupted time?

Let’s assume for your average week you carve out sixty minutes of uninterrupted time each day to do meaningful work, then, doing as I propose – spending thirty minutes planning and sixty minutes doing something meaningful every day – increases your meaningful work by 50%. Not bad. And if for your average week you currently spend thirty contiguous minutes each day doing deep work, the proposed ninety-minute arrangement increases your meaningful work by 200%. A big deal. And if you only work for thirty minutes three out of five days, the ninety-minute arrangement increases your meaningful work by 400%. A night and day difference.

Question: How many times per week do you spend thirty minutes of uninterrupted time working on the most important things? How would things change if every day you spent thirty minutes planning and sixty minutes doing the most important work?

Great idea, but with today’s business culture there’s no way to block out ninety minutes of uninterrupted time. To that I say, before going to work, plan for thirty minutes at home. And set up a sixty-minute recurring meeting with yourself first thing every morning and do sixty minutes of uninterrupted work. And if you can’t sit at your desk without being interrupted, hold the sixty-minute meeting with yourself in a location where you won’t be interrupted. And, to make up for the thirty minutes you spent planning at home, leave thirty minutes early.

No way. Can’t do it. Won’t work.

It will work. Here’s why. Over the course of a month, you’ll have done at least 50% more real work than everyone else. And, because your work time is uninterrupted, the quality of your work will be better than everyone else’s. And, because you spend time planning, you will work on the most important things. More deep work, higher quality working conditions, and regular planning. You can’t beat that, even if it’s only sixty to ninety minutes per day.

The math works because in our normal working mode, we don’t spend much time working in an uninterrupted way. Do the math for yourself. Sum the number of minutes per week you spend working at least thirty minutes at time. And whatever the number, figure out a way to increase the minutes by 50%. A small number of minutes will make a big difference.

Image credit – NASA Goddard Space Flight Center

The Slow No

When there’s too much to do and too few to do it, the natural state of the system is fuller than full. And in today’s world we run all our systems this way, including our people systems.

When there’s too much to do and too few to do it, the natural state of the system is fuller than full. And in today’s world we run all our systems this way, including our people systems.

A funny thing happens when people’s plates are full – when a new task is added an existing one hits the floor. This isn’t negligence, it’s not the result of a bad attitude and it’s not about being a team player. This is an inherent property of full plates – they cannot support a new task without another sliding off. And drinking glasses have this same interesting property – when full, adding more water just gets the floor wet.

But for some reason we think people are different. We think we can add tasks without asking about free capacity and still expect the tasks to get done. What’s even more strange – when our people tell us they cannot get the work done because they already have too much, we don’t behave like we believe them. We say things like “Can you do more things in parallel?” and “Projects have natural slow phases, maybe you can do this new project during the slow times.” Let’s be clear with each other – we’re all overloaded, there are no slow times.

For a long time now, we’ve told people we don’t want to hear no. And now, they no longer tell us. They still know they can’t get the work done, but they know not to use the word “no.” And that’s why the Slow No was invented.

The Slow No is when we put a new project on the three year road map knowing full-well we’ll never get to it. It’s not a no right now, it’s a no three years from now. It’s elegant in its simplicity. We’ll put it on the list; we’ll put it in the queue; we’ll put it on the road map. The trick is to follow normal practices to avoid raising concerns or drawing attention. The key to the Slow No is to use our existing planning mechanisms in perfectly acceptable ways.

There’s a big downside to the Slow No – it helps us think we’ve got things under control when we don’t. We see a full hopper of ideas and think our future products will have sizzle. We see a full road map and think we’re going to have a huge competitive advantage over our competitors. In both situations, we feel good and in both situations, we shouldn’t. And that’s the problem. The Slow No helps us see things as we want them and blocks us from seeing them as they are.

The Slow No is bad for business, and we should do everything we can to get rid of it. But, it’s engrained behavior and will be with us for the near future. We need some tools to battle the dark art of the Slow No.

The Slow No gives too much value to projects that are on the list but inactive. We’ve got to elevate the importance of active, fully-staffed projects and devalue all inactive projects. Think – no partial credit. If a project is active and fully-staffed, it gets full credit. If it’s inactive (on a list, in the queue, or on the road map) it gets zero credit. None. As a project, it does not exist.

To see things as they are, make a list of the active, fully-staffed projects. Look at the list and feel what you feel, but these are the only projects that matter. And for the road map, don’t bother with it. Instead, think about how to finish the projects you have. And when you finish one, start a new one.

The most difficult element of the approach is the valuation of active but partially-staffed projects. To break the vice grip of the Slow No, think no partial credit. The project is either fully-staffed or it isn’t And if it’s not fully-staffed, give the project zero value. None. I know this sounds outlandish, but the partially-staffed project is the slippery slope that gives the Slow No its power.

For every fully-staffed project on your list, define the next project you’ll start once the current one is finished. Three active projects, three next projects. That’s it. If you feel the need to create a road map, go for it. Then, for each active project, use the road map to choose the next projects. Again, three active projects, three next projects. And, once the next projects are selected, there’s no need to look at the road map until the next projects are almost complete.

The only projects that truly matter are the ones you are working on.

Image credit – DaPuglet

For top line growth, think no-to-yes.

Bottom line growth is good, but top line growth is better. But if you want to grow the bottom line, ignore labor costs and reduce material costs. Labor cost is only 5-10% of product cost. Stop chasing it, and, instead, teach your design community to simplify the product so it uses fewer parts and design out the highest cost elements.

Bottom line growth is good, but top line growth is better. But if you want to grow the bottom line, ignore labor costs and reduce material costs. Labor cost is only 5-10% of product cost. Stop chasing it, and, instead, teach your design community to simplify the product so it uses fewer parts and design out the highest cost elements.

Where the factory creates bottom line growth, top line growth is generated in the market/customer domain. The best way I know to grow the top line is to broaden the applicability of your products and services. But, before you can broaden applicability, you’ve got to define applicability as it is. Define the limits of what your product can do – how much it can lift, how fast it can run a calculation and where it can be used. And for your service, define who can use it, where it can be used and what elements without customer involvement. And with the limits defined, you know where top line growth won’t come from.

Radical top line growth comes only when your products and services can be used in new applications. Sure, you can train your sales force to sell more of what you already have, but that runs out of gas soon enough. But, real top line growth comes when your services serve new customers in new ways. By definition, if you’re not trying to make your product work in new ways, you’re not going to achieve meaningful top line growth. And by definition, if you’re not creating new functionality for your services, you might as well be focusing on bottom line growth.

If your product couldn’t do it and now it can, you’re doing it right. If your service couldn’t be used by people that speak Chinese and now it can, you’re on your way. If your product couldn’t be used in applications without electricity and now it can, you’re on to something. If your service couldn’t run on a smartphone and now it can, well, you get the idea.

For the acid test, think no-to-yes.

If your product can’t work in application A, you can’t sell it to people who do that work. If your service can’t be used by visually impaired people, you’re not delivering value to them and they won’t buy it. Turning can’t into can is a big deal. But you’ve got to define can’t before you can turn it into can. If you want top line growth, take the time to define the limits of applicability.

No-to-yes is powerful because it creates clarity. It’s easy to know when a project will create no-to-yes functionality and when it won’t. And that makes it easy to stop projects that don’t deliver no-to-yes value and start projects that do.

No-to-yes is the key element of a compete-with-no-one approach to business.

image credit – liebeslakritze

How to Avoid a Cliff

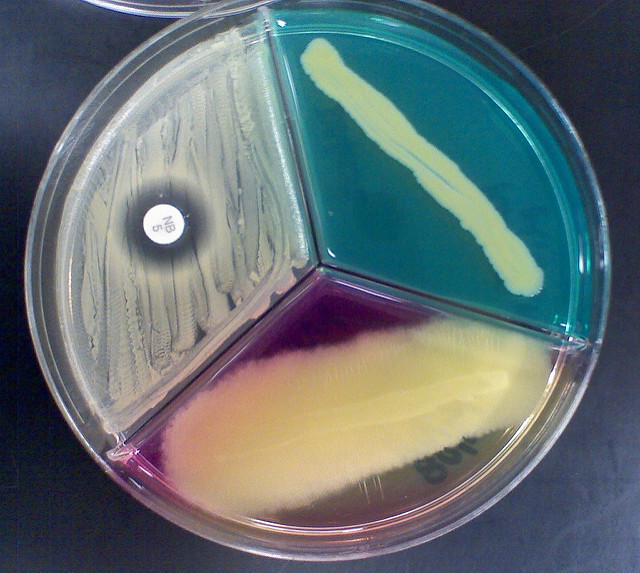

Much like living organisms continually evolve to secure their place in the future, technological systems can be thought to display similar evolutionary behavior. Viruses mutate so some of them can defeat the countermeasures of their host and live to fight another day. Technological systems, as an expression of a company’s desire to survive, evolve to defeat the competition and live to pay another dividend.

Much like living organisms continually evolve to secure their place in the future, technological systems can be thought to display similar evolutionary behavior. Viruses mutate so some of them can defeat the countermeasures of their host and live to fight another day. Technological systems, as an expression of a company’s desire to survive, evolve to defeat the competition and live to pay another dividend.

There are natural limits to evolutionary success in any single direction. When one trait is improved it pushes on the natural limits imposed by the environment. For example, a bacterium let loose in a friendly Petri dish will replicate until it eats all the food in the dish. Or, on a longer timescale, if the mass of a bird increases over generations when its food source is plentiful, the bird will get larger but will also get less agile. The predators who couldn’t catch the fast, little bird of old can easily catch and eat the sluggish heavyweight. In that way, there’s an edge condition created by the environmental Petri dishes and predators. And it’s the same with technological systems.

Companies and their technological systems evolve within their competitive environment by scanning the fitness landscape and deciding where to try to improve. The idea is to see preferential lines of improvement and create new technologies to take advantage of them. Like their smaller biological counterparts, companies are minimum energy creatures and want to maximize reward (profit) with minimum effort (expense) and will continue to leverage successful lines of evolution until it senses diminishing returns.

The diminishing returns are a warning sign that the company is approaching an edge condition (a Petri dish of a finite size). In landscape lingo, there’s a cliff on the horizon. In technology lingo, the rate of improvement of the technology is slowing. In either language, the edge is near and it’s time to evolve in a new direction because this current one is out of gas.

Like the bird whose mass increases over the generations when food is readily available, companies also get fat and slow when they successfully evolve in a single direction for too long. And like the bird, they get eaten by a more agile competitor/predator. And just as the replication rate of the bacterium accelerates as the food in the Petri dish approaches zero, a company that doesn’t react to a slowing rate of technological improvement is sure to outlive its business model.

Biology and technology are similar in that they try new things (create variants of themselves) in order to live another day. But there’s a big difference – where biology is blind (it doesn’t know what will work and what won’t), technology is sighted (people that create use their understanding to choose the variants they think will work best). And another difference is that biological evolution can build only on viable variants where technology can use mental models as scaffolds to skip non-viable embodiments to cross a chasm.

There’s no need to fall off the cliff. As a leading indicator, monitor the rate of improvement of your technology. If its rate of improvement is still accelerating, it’s time to develop the next line of evolution. If its rate is declining, you waited too long. It’s time to double down on two new lines of evolution because you’re behind the curve. And remember, like with the population of bacteria in the Petri dish, sales will keep growing right up until the business model runs out of food or a competitor eats you.

Image credit — Amanda

With novelty, less can be more.

When it’s time to create something new, most people try to imagine the future and then put a plan together to make it happen. There’s lots of talk about the idealize future state, cries for a clean slate design or an edict for a greenfield solution. Truth is, that’s a recipe for disaster. Truth is, there is no such thing as a clean slate or green field. And because there are an infinite number of future states, it’s highly improbable your idealized future state is the one the universe will choose to make real.

When it’s time to create something new, most people try to imagine the future and then put a plan together to make it happen. There’s lots of talk about the idealize future state, cries for a clean slate design or an edict for a greenfield solution. Truth is, that’s a recipe for disaster. Truth is, there is no such thing as a clean slate or green field. And because there are an infinite number of future states, it’s highly improbable your idealized future state is the one the universe will choose to make real.

To create something new, don’t look to the future. Instead, sit in the present and understand the system as it is. Define the major elements and what they do. Define connections among the elements. Create a functional diagram using blocks for the major elements, using a noun to name each block, and use arrows to define the interactions between the elements, using a verb to label each arrow. This sounds like a complete waste of time because it’s assumed that everyone knows how the current state system behaves. The system has been the backbone of our success, of course everyone knows the inputs, the outputs, who does what and why they do it.

I have created countless functional models of as-is systems and never has everyone agreed on how it works. More strongly, most of the time the group of experts can’t even create a complete model of the as-is system without doing some digging. And even after three iterations of the model, some think it’s complete, some think it’s incomplete and others think it’s wrong. And, sometimes, the team must run experiments to determine how things work. How can you imagine an idealized future state when you don’t understand the system as it is? The short answer – you can’t.

And once there’s a common understanding of the system as it is, if there’s a call for a clean sheet design, run away. A call for a clean sheet design is sure fire sign that company leadership doesn’t know what they’re doing. When creating something new it’s best to inject the minimum level of novelty and reuse the rest (of the system as it is). If you can get away with 1% novelty and 99% reuse, do it. Novelty, by definition, hasn’t been done before. And things that have never been done before don’t happen quickly, if they happen at all. There’s no extra credit for maximizing novelty. Think of novelty like ghost pepper sauce – a little goes a long way. If you want to know how to handle novelty, imagine a clean sheet design and do the opposite.

Greenfield designs should be avoided like the plague. The existing system has coevolved with its end users so that the system satisfies the right needs, the users know how to use the system and they know what to expect from it. In a hand-in-glove way, the as-is system is comfortable for end users because it fits them. And that’s a big deal. Any deviation from baseline design (novelty) will create discomfort and stress for end users, even if that novelty is responsible for the enhancement you’re trying to deliver. Novelty violates customer expectations and violating customer expectations is a dangerous game. Again, when you think novelty, think ghost peppers. If you want to know how to handle novelty, imagine a green field and do the opposite.

This approach is not incrementalism. Where you need novelty, inject it. And where you don’t need it, reuse. Design the system to maximize new value but do it with minimum novelty. Or, better still, offer less with far less. Think 90% of the value with 10% of the cost.

Image credit – Laurie Rantala

Don’t trust your gut, run the test.

At first glance, it seems easy to run a good test, but nothing can be further from the truth.

At first glance, it seems easy to run a good test, but nothing can be further from the truth.

The first step is to define the idea/concept you want to validate or invalidate. The best way is to complete one of these two sentences: I want to learn that [type your idea here] is true. Or, I want to learn that [enter your idea here] is false.

Next, ask yourself this question: What information do I need to validate (or invalidate) [type your idea here]? Write down the information you need. In the engineering domain, this is straightforward: I need the temperature of this, the pressure of that, the force generated on part xyz or the time (in seconds) before the system catches fire. But for people-related ideas, things aren’t so straightforward. Some things you may want to know are: how much will you pay for this new thing, how many will you buy, on a scale of 1 to 5 how much do you like it?

Now the tough part – how will you judge pass or fail? What is the maximum acceptable temperature? What is the minimum pressure? What is the maximum force that can be tolerated? How many seconds must the system survive before catching fire? And for people: What is the minimum price that can support a viable business? How many must they buy before the company can prosper? And if they like it at level 3, it’s a go. And here’s the most importance sentence of the entire post:

The decision criteria must be defined BEFORE running the test.

If you wait to define the go/no-go criteria until after you run the test and review the data, you’ll adjust the decision criteria so you make the decision you wanted to make before running the test. If you’re not going to define the decision criteria before running the test, don’t bother running the test and follow your gut. Your decision will be a bad one, but at least you’ll save the time and money associated with the test.

And before running the test, define the test protocol. Think recipe in a cookbook: a pinch of this, a quart of that, mix it together and bake at 350 degrees Fahrenheit for 40 minutes. The best protocols are simple and clear and result in the same sequence of events regardless of who runs the test. And make sure the measurement method is part of the protocol – use this thermocouple, use that pressure gauge, use the script to ask the questions about price and the number they’d buy.

And even with all this rigor, good judgement is still part of the equation. But the judgment is limited to questions like: did we follow the protocol? Did the measurement system function properly? Do the initial assumptions still hold? Did anything change since we defined the learning objective and defined the test protocol?

To create formal learning objectives, to write well-defined test protocols and to formalize the decision criteria before running the test require rigor, discipline, time and money. But, because the cost of making a bad decision is so high, the cost of running good tests is a bargain at twice the price.

Image credit – NASA Goddard Flight Center

Innovation in three words – Solve Different Problems

With innovation, novel solutions pay the bills – a new solution provides new value for the customer and the customer buys it from you. The trick, however, is to come up with novel solutions. To improve the rate and quality of novel solutions, there’s usually a focus on new tools, new problem-solving methods and training on both. The idea is get better at moving from problem to solution. There’s certainly room for improvement in our problem-solving skills, but I think the pot of gold is hidden elsewhere.

With innovation, novel solutions pay the bills – a new solution provides new value for the customer and the customer buys it from you. The trick, however, is to come up with novel solutions. To improve the rate and quality of novel solutions, there’s usually a focus on new tools, new problem-solving methods and training on both. The idea is get better at moving from problem to solution. There’s certainly room for improvement in our problem-solving skills, but I think the pot of gold is hidden elsewhere.

Because novel solutions reside in uncharted design space, it follows that novel solutions will occur more frequently if the problem-solvers are pointed toward new design space. And to make sure they don’t solve in the tired, old design space of success, constraints are used to wall it off. Rule 1 – point the solvers toward new design space. Rule 2 – wall off the over-planted soil of success.

The best way to guide the problems solvers toward fertile design space is to create different problems for them to solve. And this guide-the-solvers thinking is a key to the success of the IBE (Innovation Burst Event), where Design Challenges are created in a way that forces the solvers from the familiar. And it’s these Design Challenges that ARE the new problems that bring the new solutions. And to wall off old design space, the Design Challenges use creatively curated constraints to make it abundantly clear that old solutions won’t cut it.

Before improving the back-end problem solving process, why not change the front- end problem selecting process?

Chose to solve different problems, then learn to solve them differently.

Image credit – Rajarshi MITRA

Mike Shipulski

Mike Shipulski