Archive for November, 2017

A three-pronged approach for making progress

When you’re looking to make progress, the single most important skill is to see waiting as waiting.

The first place to look for waiting is the queue in front of a shared resource. Like taking a number at the deli, you queue up behind the work that got there first and your work waits its turn. And when the situation turns bad, prioritization meeting spring up to argue about the importance of one bit of work over another. Those meetings are a sure-fire sign of ineffectiveness. When these meetings spring up, it’s time to increase capacity of the shared resource to stop waiting and start making progress.

Another place to look for waiting is the process to schedule a meeting with high-level leaders. Their schedules are so full (efficiency over effectiveness) the next open meeting slot is next month. Let me translate – “As a senior leader and decision maker, I want you to delay the business-critical project until I carve out an hour so you can get me up to speed and I can tell you what to do.” The best project managers don’t wait. They schedule the meeting three weeks from now, make progress like their hair is on fire and provide a status update when the meeting finally happens. And the smartest leaders thank the project managers for using their discretion and good judgment.

A variant of the wait-for-the-most-important-leader theme is the never-ending-series-of-meetings-where-no-decisions-are-made scenario. The classic example of this unhealthy lifestyle is where a meeting to make a decision spawns a never-ending series of weekly meetings with 12 or more regular attendees where the initial agenda of making a decision death spirals into an ever-changing, and ultimately disappearing agenda. Everyone keeps meeting, but no one remembers why. And the decision is never made. The saddest part is that no one remembers that project is blocked by the non-decision.

The first place to look for waiting is the queue in front of a shared resource. Like taking a number at the deli, you line up behind the work that got there first and your work waits its turn. And when the situation turns bad, prioritization meeting spring up to argue about the importance of one bit of work over another. Those meetings are a sure-fire sign of ineffectiveness. It’s time to increase capacity of the shared resource to stop waiting and start making progress.

And the deadliest waiting is the waiting that we no longer see as waiting. The best example of this crippling non-waiting waiting is when we cannot work the critical path and, instead, we work on a task of secondary importance. We kid ourselves into thinking we’re improving efficiency when, in fact, we’re masking the waiting and enabling the poor decision making that starved the project of the resources it needs to work the critical path. Whether you work a non-critical path task or not, when you can’t work the critical path for a week, you delay project completion by a week. That’s a rule.

Instead of spending energy working a non-critical path task, it’s better for everyone if you do nothing. Sit at your desk and play solitaire on your computer or surf the web. Do whatever it takes for your leader to recognize you’re not making progress. And when your leader tries to chastise you, tell them to do their job and give you what you need to work the critical path.

There’s two types of work – value-added work and non-value-added work. Value-added work happens when you complete a task on the critical path. Non-value-added work happens when you wait, when you do work that’s not on the critical path, when you get ready to do work and when you clean up after doing work. In most processes, the ratio of non-value-added to value-added work is 20:1 to 200:1. Meaning, for every hour of value-added work there are twenty to two hundred hours of non-value-added work.

If you want to make progress, don’t improve how you do your value-added work. Instead, identify the non-value-added work you can stop and stop it. In that way, without changing how you do an hour long value-added task, you can eliminate twenty to two hundred hours wasted effort.

Here’s the three-pronged approach for making progress:

Prong one – eliminate waiting. Prong two – eliminate waiting. Prong three – eliminate waiting.

Image credit João Lavinha

Additive Manufacturing’s Holy Grail

The holy grail of Additive Manufacturing (AM) is high volume manufacturing. And the reason is profit. Here’s the governing equation:

The holy grail of Additive Manufacturing (AM) is high volume manufacturing. And the reason is profit. Here’s the governing equation:

(Price – Cost) x Volume = Profit

The idea is to sell products for more than the cost to make them and sell a lot of them. It’s an intoxicatingly simple proposition. And as long as you look only at the volume – the number of products sold per year – life is good. Just sell more and profits increase. But for a couple reasons, it’s not that simple. First, volume is a result. Customers buy products only when those products deliver goodness at a reasonable price. And second, volume delivers profit only when the cost is less than the price. And there’s the rub with AM.

Here’s a rule – as volume increases, the cost of AM is increasingly higher than traditional manufacturing. This is doubly bad news for AM. Not only is AM more expensive, its profit disadvantage is particularly troubling at high volumes. Here’s another rule – if you’re looking to AM to reduce the cost of a part, look elsewhere. AM is not a bottom-feeder technology.

If you want to create profits with AM, use it to increase price. Use it to develop products that do more and sell for more. The magic of AM is that it can create novel shapes that cannot be made with traditional technologies. And these novel shapes can create products with increased function that demand a higher price. For example, AM can create parts with internal features like serpentine cooling channels with fine-scale turbulators to remove more heat and enable smaller products or products that weigh less. Lighter automobiles get better fuel mileage and customers will pay more. And parts that reduce automobile weight are more valuable. And real estate under the hood is at a premium, and a smaller part creates room for other parts (more function) or frees up design space for new styling, both of which demand a higher price.

Now, back to cost. There’s one exception to cost rule. AM can reduce total product cost if it is used to eliminate high cost parts or consolidate multiple parts into a single AM part. This is difficult to do, but it can be done. But it takes some non-trivial cost analysis to make the case. And, because the technology is relatively new, there’s some aversion to adopting AM. An AM conversion can require a lot of testing and a significant cost reduction to take the risk and make the change.

To win with AM, think more function AND consolidation. More (or new) function to support a higher price (and increase volume) and reduced cost to increase profit per part. Don’t do one or the other. Do both. That’s what GE did with its AM fuel nozzle in their new aircraft engines. They combined 20 parts into a single unit which weighed 25 percent less than a traditional nozzle and was more than five times as durable. And it reduced fuel consumption (more function, higher price).

AM is well-established in prototyping and becoming more established in low-volume manufacturing. The holy grail for AM – high volume manufacturing – will become a broad reality as engineers learn how to design products to take advantage of AM’s unique ability to make previously un-makeable shapes and learn to design for radical part consolidation.

More function AND radical part consolidation. Do both.

Image credit – Les Haines

Make It Easy

When you push, you make it easy for people resist. When you break trail, you make it easy for them to follow.

When you push, you make it easy for people resist. When you break trail, you make it easy for them to follow.

Efficiency is overrated, especially when it interferes with effectiveness. Make it easy for effectiveness to carry the day.

You can push people off a cliff or build them a bridge to the other side. Hint – the bridge makes it easy.

Even new work is easy when people have their own reasons for doing it.

Making things easier is not easy.

Don’t tell people what to do. Make it easy for them to use their good judgement.

Set the wrong causes and conditions and creativity screeches to a halt. Set the right ones and it flows easily. Creativity is a result.

Don’t demand that people pull harder, make it easier for them to pull in the same direction.

Activity is easy to demonstrate and progress isn’t. Figure out how to make progress easier to demonstrate.

The only way to make things easier is to try to make them easier.

Image credit – Richard Hurd

The Power of Surprise

There’s disagreement on what is creative, innovative and disruptive. And there is no set of hard criteria to sort concepts into the three categories. Stepping back a bit, a lesser but still important sorting is an in-or-out categorization. Though not as good as discerning among the three, it is useful to decide if a new concept is in (one of the three) or out (not).

There’s disagreement on what is creative, innovative and disruptive. And there is no set of hard criteria to sort concepts into the three categories. Stepping back a bit, a lesser but still important sorting is an in-or-out categorization. Though not as good as discerning among the three, it is useful to decide if a new concept is in (one of the three) or out (not).

The closest thing to an acid test is assessment of the emotional response generated by a new concept. Here are some responses that I consider tell-tail signs of powerful ideas/concepts worthy of the descriptors creative, innovative, or disruptive.

When first shown, a prototype creates fear and defensiveness. The fear signals that the prototype threatens the status quo and defensiveness is objective evidence of the fear.

When first explained, a new concept creates anger and aggression. Because the concept doesn’t play by the rules, it disrespects everything holy, and the unfairness spawns indigence.

After some time, the dismissive comments about the new prototype fade and turn to discussions colored by deep sadness as the gravity of the situation hits home.

But the best leading indicator is surprise. When a test result doesn’t match your expectations, it generates surprise. And since your expectations are built on your mental models, surprising concepts contradict your mental models. And since your mental models are formed by successful experiences, prototypes that create surprise violate previous success.

If you’re surprised by a new concept, it’s worth a deeper look. If you’re not surprised, move on.

If you’re not tolerant of surprise, you should be. And if you are tolerant of surprise, it’s time to become fervent.

Image credit – Raul Pop

The one good way to change behavior.

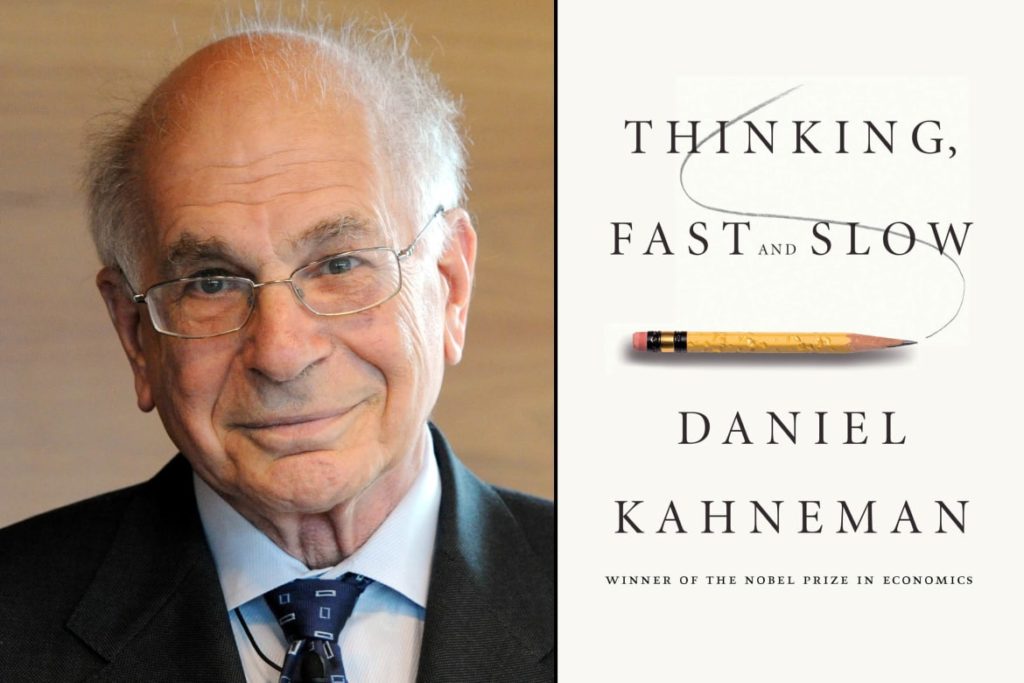

There’s one good way to change behavior. But don’t take my word for it, take Daniel Kahneman’s, psychologist who was awarded the Nobel Prize in Economic Sciences. In Freakonomics Radio’s podcast How to Launch a Behavioral Change Revolution, Kahneman explains how to achieve change in behavior. His explanation is short [30:35 – 35:21] and good.

There’s one good way to change behavior. But don’t take my word for it, take Daniel Kahneman’s, psychologist who was awarded the Nobel Prize in Economic Sciences. In Freakonomics Radio’s podcast How to Launch a Behavioral Change Revolution, Kahneman explains how to achieve change in behavior. His explanation is short [30:35 – 35:21] and good.

Kahneman describes a theory of Kurt Lewin, his academic grandfather, where behavior is an equilibrium, a balance between driving forces that push for change and restraining forces that hold back change. Kahneman goes on to describe Lewin’s insight. “Lewin’s insight was that if you want to achieve change in behavior, there is one good way to do it and one bad way. The good way is by diminishing restraining forces, not by increasing the driving forces. That turns out to be profoundly non-intuitive.”

Usually, when we want someone to change, we push them in the direction we want them to go. Kahneman says this approach is natural, but ineffective. He offers a different approach – “Instead of asking how can I get him or her to do it, it starts with a question of why isn’t she doing it already? Go one-by-one, systematically, and you ask ‘What can I do to make it easier for that person to move?’”

What would happen if instead of pushing someone to change, you understand what’s in the way and eliminated the restraining force? I don’t know, but I’m going to give it a try.

Kahneman goes on to describe how to make things easier for a person to move. He says “…the way to make things easier is almost always by controlling the individual’s environment…by just making it easier.” Sounds pretty simple – change people’s environment to make it easier for them to move toward the desired behavior. But, we don’t do it that way.

Kahneman gives more detail. “Are there incentives that work against it? Let’s change the incentives.” And then he gives a simple example. “I want to influence B, but there is A in the background and it’s A who is a restraining force on B, let’s work on A, not on B.”

I urge you to listen to the short segment to hear Kahneman’s words for yourself. His ideas really hit home when you hear them from him.

Mike Shipulski

Mike Shipulski