Boothroyd Dewhurst DFMA Helps Slash Warranty Costs and Boost Factory Floor Profits 600 Percent at Hypertherm

Five-year implementation of DFMA software by Hypertherm creates higher profits and strong business model for improving U.S. global competitiveness

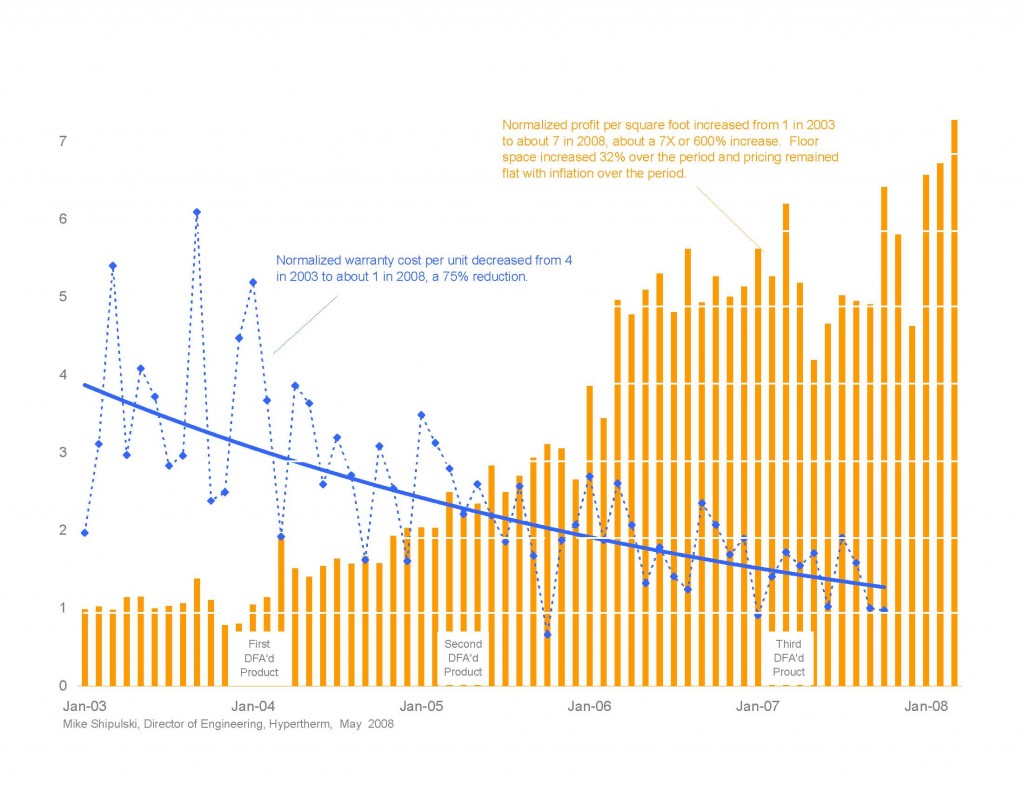

WAKEFIELD, R.I., and HANOVER, N.H.,USA, June 2, 2008—Hypertherm, the world leader in plasma metal cutting technology, has achieved a 600 percent increase in profit per square foot of factory floor space using Boothroyd Dewhurst, Inc., Design for Manufacture and Assembly (DFMA®) software within a five-year redesign program. Correspondingly, warranty cost per unit has declined more than 75 percent during that same period, from January 2003 to January 2008.

“We started with a vision to make radical improvements in both product performance and product economies,” says Mike Shipulski, Hypertherm’s director of engineering. “Hypertherm met both of these goals by aggressively applying Boothroyd Dewhurst’s software within our existing programs for robust design and lean manufacturing. We found their product simplification software made it easy for us to improve a product’s performance-to-cost ratio. Moreover, we learned that DFMA ideas and financial estimates also lead to profound savings beyond labor and part cost, creating a domino effect ‘downstream’ in operational areas of our organization.”

All technology development, product development, and manufacturing of Hypertherm’s plasmacutting equipment is done in New Hampshire. By simplifying product designs, Hypertherm has decreased labor expenses by 70 percent on redesigned products. That achievement has proven that design simplification is a fundamental and highly effective competitive strategy for negating the effect of cheap foreign labor rates. In fact, Hypertherm actually sells more of its products in regions like Europe, Asia, and South America than in the United States. More of the world’s cutting tables are equipped with a Hypertherm mechanized system than all other plasma brands combined.

Other Hypertherm five-year benchmarks tied to its engineering innovation and management practices include:

Greater private stock value and profit-sharing for all associates

Flat product prices to customers (inflation-based increases only), despite rapidly rising material and outside business expenses

Win-win supplier strategies focused on waste reduction rather than reducing supplier margins

“Hypertherm is an outstanding business model of what can be accomplished by deploying engineering technology as a foundational strategy,” says John Gilligan, president of Boothroyd Dewhurst. “They are integrating their DFMA program with lean concepts, smart use of automation, employee empowerment, and other outstanding approaches. Most unique, from our perspective, is that Hypertherm carefully tracks cause and effect—from the DFMA design station to the shipping dock. They monitor the correlation between part count reduction and business improvement. A 600 percent increase in profit per square foot of factory floor space in five years is a productivity feat of world-class proportions. These results should send a strong signal to other U.S. manufacturing industries about what can be achieved through redesign,” said Gilligan.

Boothroyd Dewhurst has released a DFMA survey-roundtable on the relationship between part count reduction and savings in operational costs that includes measurements and comments from many leading U.S. manufacturers. The report is available at http://www.dfma.com/downstream/ . Nick Dewhurst of Boothroyd Dewhurst, Inc. and Mike Shipulski of Hypertherm will discuss Hypertherm’s DFMA results on June 11 at the annual DFMA Forum in Warwick, RI. For more information on the Forum go to: http://www.dfma.com/forum/index.html

About Hypertherm

Hypertherm (www.hypertherm.com) designs and manufactures the world’s most advanced plasma cutting systems for use in a variety of industries such as shipbuilding, manufacturing, and automotive repair. Its product line includes handheld and mechanized plasma systems and consumables, as well as CNC motion and height controls. Hypertherm systems are trusted for performance and reliability that results in increased productivity and profitability for tens of thousands of businesses. The New Hampshire based company’s reputation for plasma innovation dates back 40 years, to 1968, with Hypertherm’s invention of water injection plasma cutting. The company, consistently named one of the best places to work in America, has nearly 1,000 associates along with operations and partner representation worldwide.

About Boothroyd Dewhurst, Inc.

Boothroyd Dewhurst, Inc. was the first company to commercialize Design for Manufacture and Assembly (DFMA) methodologies and software tools, which make it possible to evaluate, estimate, and reduce the manufacturing cost of a product in the design phase through product simplification and cost estimation. Hundreds of Fortune 1000 companies, including Dell, John Deere, Harley-Davidson, and Whirlpool, use DFMA to cut the costs of their manufactured products and achieve design innovation in their markets. The company was founded in 1983 and received the National Medal of Technology Award in 1991. For more information about DFMA software, workshops, consulting services, and international conferences, contact Boothroyd Dewhurst, Inc., 138 Main Street, Wakefield, R.I. 02879, USA. Tel. (401) 783-5840. Fax (401) 783-6872. Web site: www.dfma.com. E-mail: info@dfma.com.

DFMA is a registered trademark of Boothroyd Dewhurst, Inc.

Mike Shipulski

Mike Shipulski